A full 14 percent of the world’s food goes to waste between harvest and store delivery, according to a United Nations Food and Agriculture Report. As Bloomberg Businessweek recently reported, the economic value of that loss is $400 billion, larger than the GDP of most nations. At a time when 820 million people go hungry every day, this loss has a social cost, too.

Against that backdrop, an emerging technology called geoblockchain offers companies a way to locate and fix deficiencies in the food supply chain.

The causes of food waste are varied and intertwined, including spoilage, inadequate storage, inefficient routing, and an unwillingness to sell food that doesn’t look “perfect” but is otherwise intact. As the UN report notes, much of the food lost is the perishable type—fruits, vegetables, and grains—that people depend on for a healthy diet.

The problem spans the globe. Europe and North America account for nearly 16 percent of the losses, second only to central and south Asia’s 20 percent. While world leaders and private corporations have pledged to halve the amount of food wasted at the retail and consumption levels by 2030, the problem of pre-retail loss remains largely unaddressed.

Cold New World

Though the UN report stresses that more research on supply chains is needed, it does suggest a way forward, emphasizing the importance of reliable physical infrastructure, efficient logistics, and analytics for tracking waste. It also highlights the need for reliable cold storage conditions.

While the ultimate solution will likely involve these and other remedies, it is safe to say that improving companies’ ability to monitor supply chains is a good place to start. If food producers could monitor their products’ condition at every step of the journey, they could understand where and how the system breaks down.

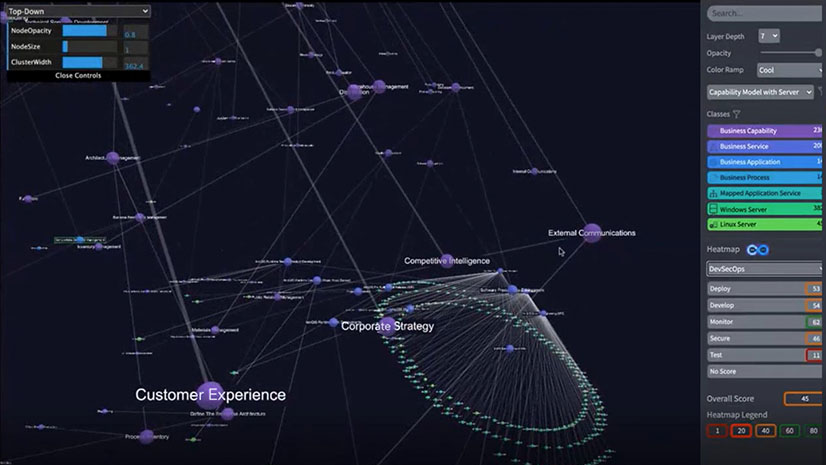

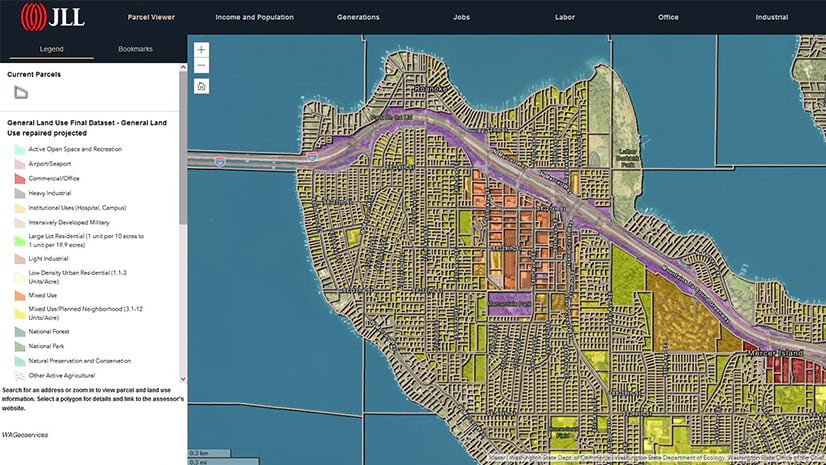

Kevin Bolger, a practice lead for artificial intelligence and machine learning at Esri, recently demonstrated a system of location intelligence for supply chains. He outlined how a geographic information system (GIS) could incorporate a geoblockchain to provide a constant overview of cold storage conditions during shipping.

Connecting the Dots

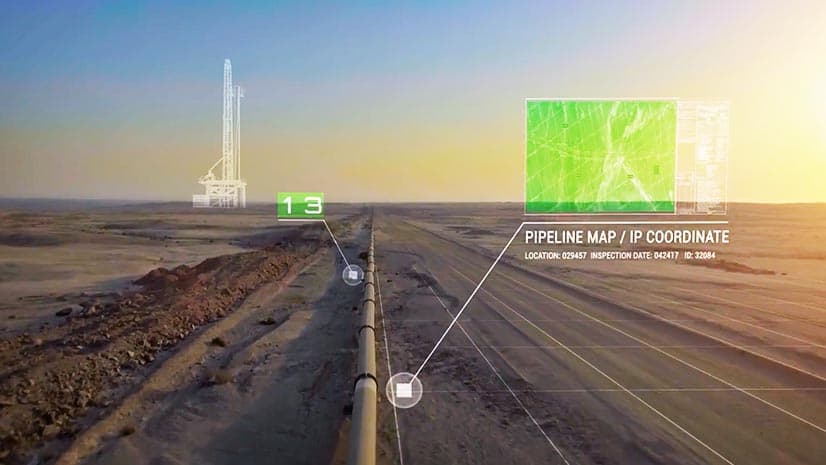

The supply chain monitoring app in this demonstration is powered by GIS technology, fed by IoT-based temperature sensors, and governed by blockchain technology.

The inner workings of blockchain are complex, but the underlying concept is simple: Imagine a transaction between two parties that is recorded in a ledger. (In the food supply chain, that might mean transferring cargo from an international shipper to a local distributor, for example.) Blockchain logs those transactions in multiple digital locations—across a distributed ledger. Anyone attempting to alter the ledger would have to change every copy.

A series of such transactions becomes part of a “chain” of all transactions that establishes the provenance and condition of the goods. For supply chain monitoring, the transactions occur at various locations where products are observed or change hands. In the cold storage example, every temperature reading is recorded as a transaction.

Location intelligence is at the heart of this supply chain analysis and provides important context. With a location-specific view on a GIS map, a supply chain manager can see exactly where food spoilage problems arise. The geoblockchain provides an immutable record of temperature readings and where each occurred on the chain.

Paying the Bill

Preventing spoilage is not the only reason businesses in the food sector use location intelligence to monitor supply chains. One of the largest food and beverage companies in Thailand uses GIS to monitor a 2,500-truck fleet for increased efficiency and reduced cost. Global palm oil refiner Bunge Loders Croklaan uses it to monitor whether suppliers are engaged in sustainable practices.

New business applications of location intelligence for supply chain management—including the use of geoblockchain—could reduce the $400 billion waste bill. At the same time, companies can improve their own bottom line while helping create a food supply chain that better meets the world’s needs.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

November 12, 2018 |

February 1, 2022 |

July 29, 2025 |

July 14, 2025 |