Sixty million people are directly affected by the millions of land mines that have been deployed in more than 60 states and territories around the world. Land mines kill and injure civilians, deny land use, destroy livelihoods, and disrupt access to essential services. These mines remain in the ground for years—even decades—and are still able to kill and maim long after conflicts have ended.

For more than 20 years, The HALO Trust, a humanitarian nongovernment organization, has used geospatial technology to fulfill its mission of safely clearing land mines and explosive ordnance from civilian land. Its suite of GIS and GNSS solutions have improved the quantity and quality of data that is critical to these efforts.

In recent years, the organization has adopted and adapted field-focused workflows that are not just accurate but scalable, easy to use, and—perhaps best of all—cost-effective. The combination of GIS and GNSS technologies is helping this extraordinary nonprofit organization do more to help communities around the world recover following conflict.

The Need for Accuracy

The scope and scale of land mine and ordnance clearance activities—whether urban or rural—is time-consuming and resource heavy given the often dense area of contamination. Some minefields have hundreds or even thousands of coordinates that need to be recorded.

Obtaining the high-accuracy spatial data needed to delineate and map the boundaries of suspected hazardous areas and mark specific evidence points in the field has long been a challenge. According to Jesse Hamlin, senior GIS officer for HALO, “We can’t be two, three, or four meters off. In this environment, accuracy is as essential as speed.”

The organization has relied on differential GNSS and base stations to measure distances and locate points. While this methodology is highly accurate, it requires a significant upfront investment and training for the field crews. Portability and ease of use are important considerations because HALO teams typically work in remote places and many team members who gather position data do not have technical backgrounds.

“It’s not really feasible to have every team carry a base station,” said Hamlin. “In the past, teams have had to set up and synchronize multiple base stations to begin data gathering in a minefield—and, because these are areas of conflict, theft is a concern. We have to set up in a location where it won’t get stolen during the night. Cost is also an issue as in some countries. We have hundreds of teams working in different locations and purchasing one for each team is impossible.”

He noted that advances in mobile devices with Bluetooth connectivity to real-time correction sources, such as Satellite-based Augmentation System (SBAS), virtual reference station (VRS) networks, or Precise Point Positioning (PPP) systems, opened the door for alternative solutions.

Over the last two years, HALO has deployed Trimble DA2 GNSS receivers using the Trimble Catalyst subscription-based GNSS positioning service, a technology ideal for working with ArcGIS Survey123 forms. The Trimble DA2 is a real-time kinematics (RTK)-capable GNSS receiver that relies on a simple Bluetooth connection to Android or iOS devices. The subscription-based positioning service supports bundled broadcast corrections, and it supports 60 cm, 30 cm, 10 cm, or 1 cm positioning accuracy, eliminating the need to maintain and pay for separate base station infrastructure.

“We need to limit the time spent transcribing data from a GNSS receiver to another digital document or even a piece of paper, as there’s too much chance of error. The easy-to-use interface between the DA2 to Survey123 forms is invaluable when it comes to getting our field teams up to speed,” said Hamlin. The easy integration between the receiver data and the ArcGIS Survey123 forms is especially beneficial. The system just works. “No more worries about handling base stations; it’s very portable, easy to learn and use, and we get centimeter precision,” Hamlin noted.

HALO staff particularly appreciate that the quality of survey polygons can quickly be previewed on tablets in the field. Once data is gathered and confirmed, it is submitted to ArcGIS Enterprise directly from ArcGIS Survey123. For example, not long ago nearly 600 mines were located and destroyed in one minefield in Angola, where nearly 1,300 coordinates were taken using the Trimble DA2 and ArcGIS Survey123.

“Before the DA2 GNSS, mapping this level of detail would have been impossible,” confirmed Hamlin.

Prioritizing Mine Clearance

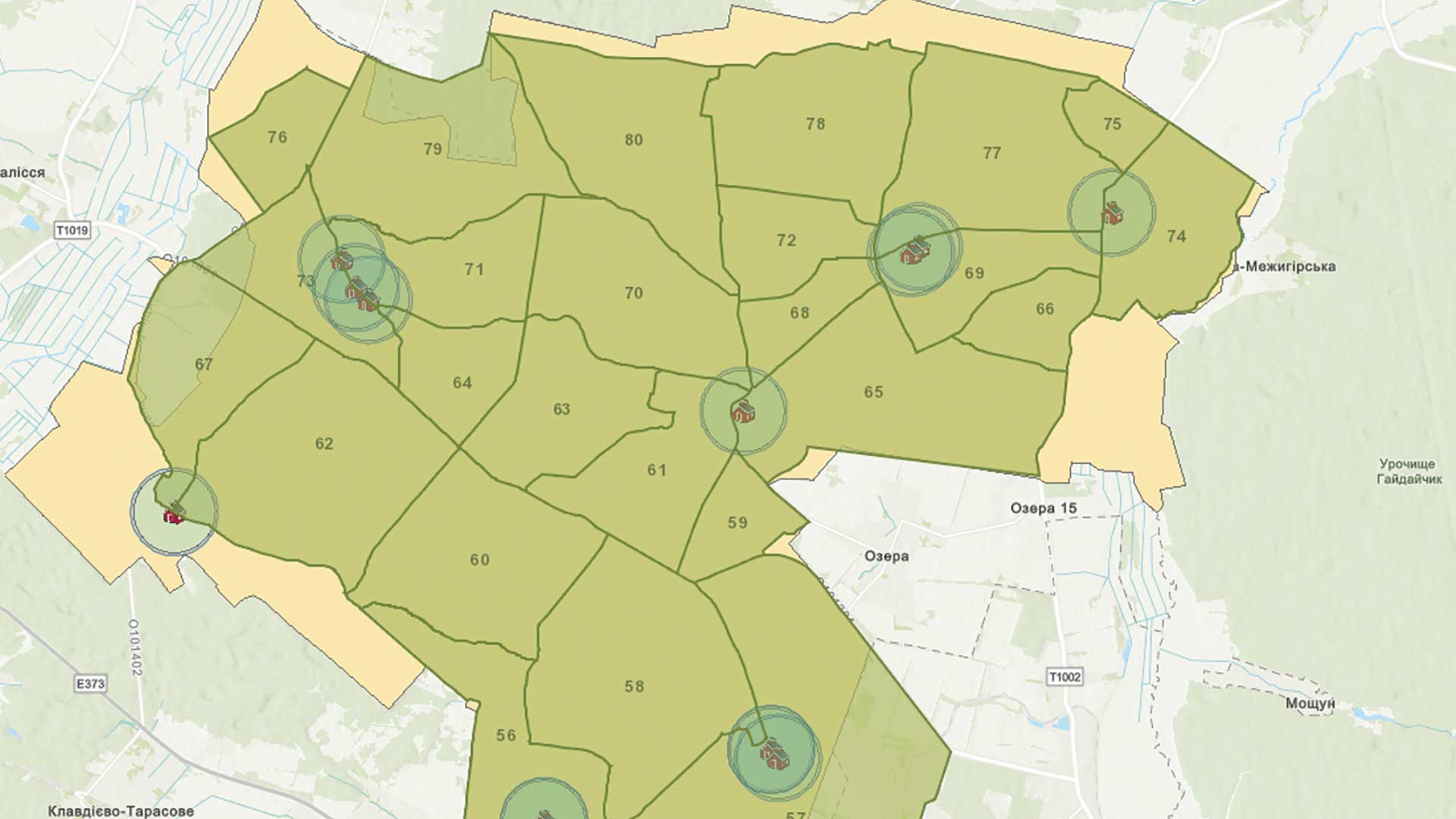

Once the data is collected, a team of supervisors back in the HALO office begins a quality assurance process to verify data accuracy and completeness. Approved data is visualized using web maps in ArcGIS Online or ArcGIS Enterprise. Survey data is analyzed in ArcGIS Pro to assess the extent of contamination and prioritize clearance. Drone and satellite imagery provides some context for the conflict and the area of concern. The map documents survey polygons and evidence points at the micro and macro levels. The data is then published as web service layers in ArcGIS Enterprise and shared across the entire program and with stakeholders.

Once mapped and verified, the clearance process is time-consuming. Within ArcGIS, the team combines satellite imagery, survey polygons, and mine evidence points so that work areas can be prioritized based on humanitarian impact and available resources. For instance, in Ukraine, the group might prioritize the clearance of minefields that impact agricultural land to help farmers growing crops to feed communities in need.

Clearance field maps are broken up into smaller packages that are downloaded to a phone or tablet. Field teams can also use offline maps created using ArcGIS Field Maps on tablets. Since the bundled correction services leverage the global Trimble RTX correction service, the Trimble Catalyst DA2 GNSS receiver is still able to work precisely in areas without reliable internet coverage using satellite-delivered correction data.

Hamlin said, “Then the clearance teams go into the areas, once again with the DA2 and Survey123 forms loaded with the map packages, to begin clearance, recording polygon positions as work is completed. The entire workflow is streamlined, clear to the operators, and highly accurate.”

AI and Mine Clearance

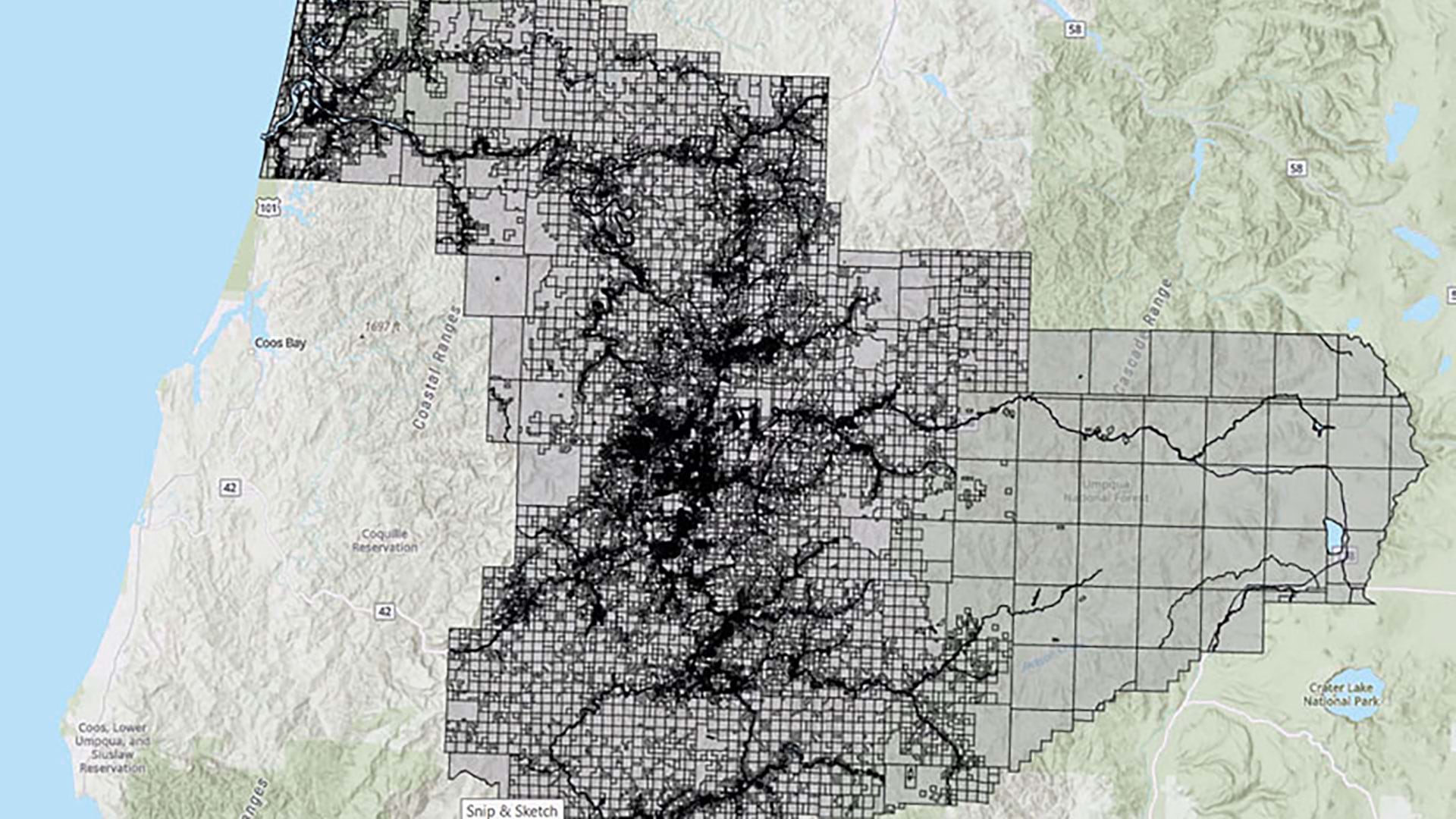

Artificial intelligence (AI) is finding its way into HALO workflows. Five or six years ago, HALO started evaluating AI and machine learning techniques in tools such as ArcGIS Pro to assess how it might support and improve various work streams.

One potential use of AI that is currently being tested is automatically detecting land mines from imagery collected by drones. Models are trained on sample images of mines. Machine learning algorithms could help detect patterns in minefields by mapping evidence such as craters from exploded anti-tank mines.

While this wouldn’t eliminate the need for field surveys to map minefields, it would help determine resource allocation and an optimal clearance approach. Similarly, the advanced intelligence could help prioritize areas for mapping and clearance based on analysis of multiple data sources. Detecting changes could reduce the need for manual surveys, which would lower costs and improve operational efficiency.

AI could also improve the analysis of damage after a conflict and quantify clearance impact metrics, such as the number of structures that have been rebuilt following a clearance. Hamlin explained, “For instance, in Ukraine, we initially assumed that we would be working in urban areas. As it turned out, the need was much greater in rural areas. When we clear a minefield, we have people that are actually building homes and farming the land right up to the border of the minefield. Tracking this rebuilding is typically very resource intensive as it would require teams to be sent around the country to assess the human activity in close proximity to cleared minefields. A solution with AI might be able to perform that analysis in minutes.”

All HALO’s technology investments, whether in GIS, GNSS, or AI, are focused on shortening the recovery time of war-torn regions. “If you look at places like Ukraine, we’re seeing an increase in the number of accidents, particularly in agricultural areas because farmers want to get back to work planting and harvesting their land to support their families and their communities—sometimes before the land mine clearance is complete,” said Hamlin. “From the land we have surveyed so far, the length of time and cost to clear the area through traditional mine clearance methods can take up to 20 years or more, depending on how long the fighting continues.”

Hamlin believes that increased capacity and resources with the deployment of technology and new methods will shorten the time to clear mines. This improvement in productivity will go a long way to helping communities recover as quickly as possible.