The construction industry is a dynamo of economic growth. Valued at $7.3 trillion in 2021, the sector accounts for 13 percent of global GDP. Fueled by government spending in some of the world’s largest economies and booming demand for new housing and infrastructure, construction firms have gone on a hiring spree to keep up with the sizzling pace of activity.

But don a hard hat and visit a typical work site, and you’re likely to see workflows that remain surprisingly analog. Site managers consult paper blueprints that don’t reflect real-time progress, while project members share files in ad hoc emails.

In an industry marked by low profit margins and intense competition, construction firms have been wary of innovations that might bring short-term disruption. That hesitance has led to consistently low productivity growth.

Signs of a shift are emerging among top firms. Billion-dollar investments in construction technology are pouring into the industry as experimentation with automation and sustainable materials is accelerating.

As the benefits of digital transformation become clear, some of the sector’s leading firms are turning to geographic information system (GIS) technology to manage the complex needs of modern-day construction. With smart maps and real-time dashboards generating data-driven insight and digital twin visualizations, the infrastructure of the future is becoming faster, safer, and more cost-effective to build.

For Construction Firms, Everything Is Spatial

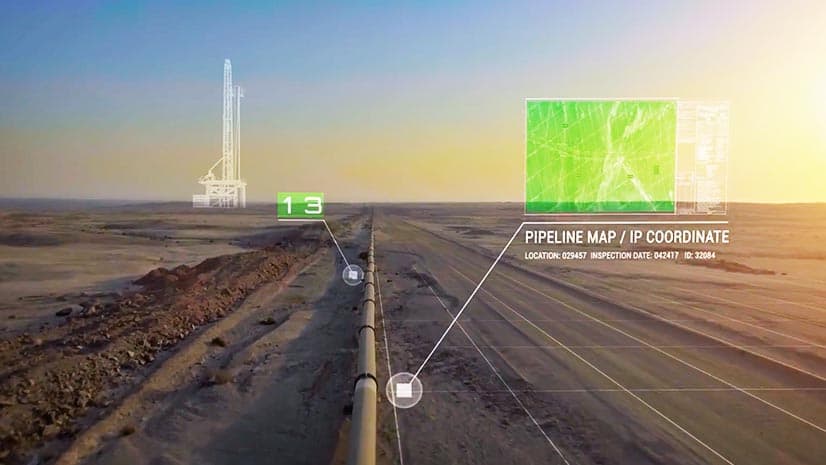

GIS is the data management technology that tracks sites, materials, people, and progress through the construction timeline, from initial site selection to ongoing maintenance.

When one of the world’s largest construction firms adopted geospatial technology, it achieved time savings of up to 40 percent through the project life cycle and cut millions in spending.

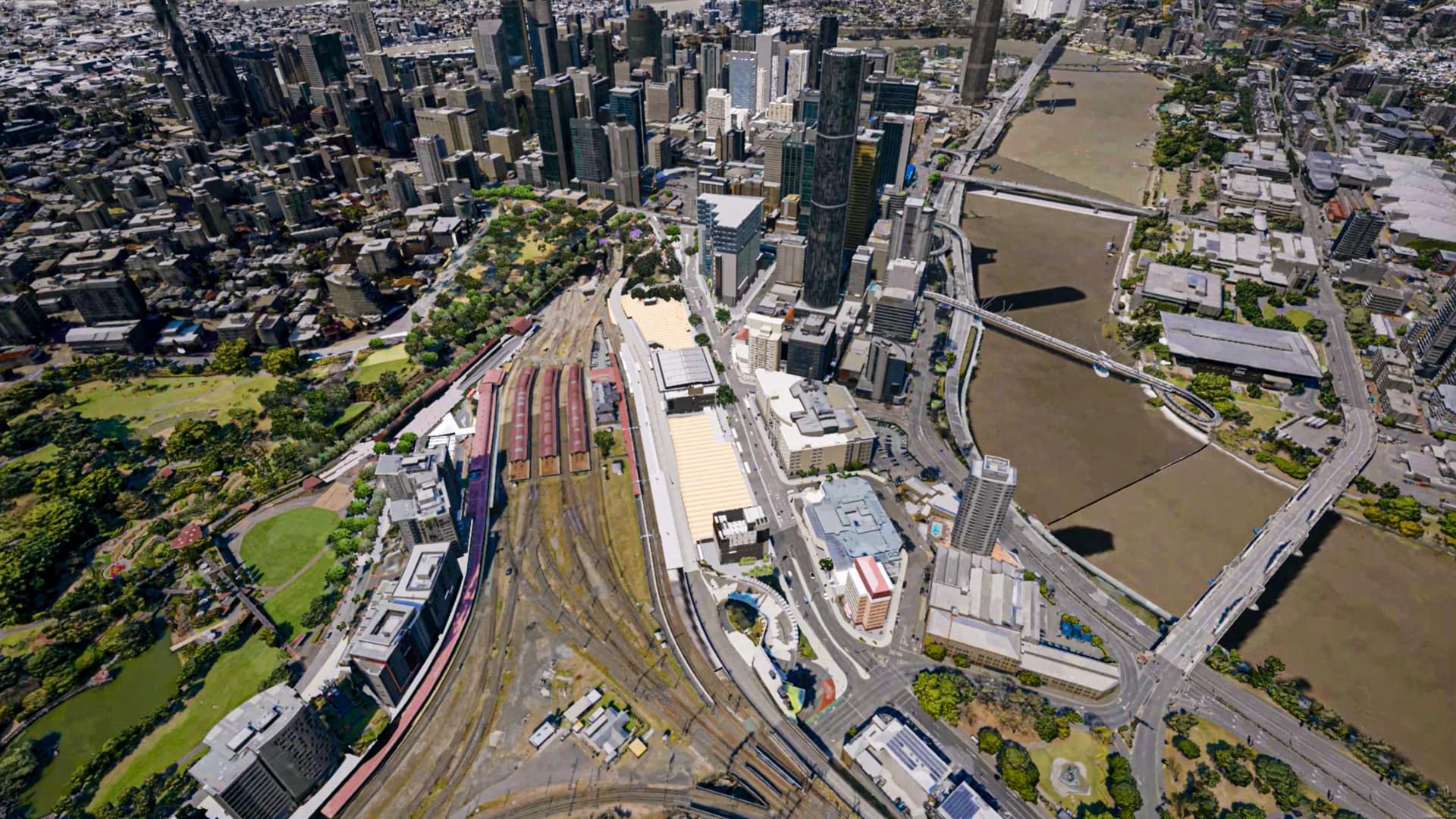

A real-time, 3D digital twin can be at the heart of such improvements. As detailed in this demonstration, a GIS digital twin supplies the context needed for smart construction decisions. For instance, a dashboard that displays a work site in the context of local supply chains can help project managers select suppliers and optimize delivery routes.

Location technology is also transforming how construction data is shared, forging more seamless collaboration. With GIS technology as the hub that integrates building information modeling (BIM) files, aerial imagery, and IoT sensors, project managers, clients, and other stakeholders see real-time progress updates in sharp visual detail.

At each stage of the construction value chain, location intelligence is leading to greater efficiency and new insights.

Design, Coordination, Budget, Scheduling—The Planning Phase

In the construction planning stage, GIS helps project leaders select a site, forecast hazards, ensure compliance, and practice sustainable design.

During site selection, for example, a planner could use digital maps to view a site’s regulatory constraints, proximity to resources, ease of access, and environmentally sensitive areas and disqualify unfavorable locations.

A digital twin is a powerful tool for scenario planning. By combining GIS and BIM data in a 3D model, construction firms can simulate hazards like sea level rise or wildfires and identify their potential impacts on planned structures. One global project management firm used a digital twin to visualize the interplay of subsurface utilities when designing a new airport concourse. That understanding saved the team from costly design decisions.

Data visualization can also help managers anticipate a project’s environmental compliance. In California, the operator of a high-speed rail system adopted GIS to monitor over 10,000 land parcels impacted by the rail line. With the technology’s data management capabilities, planners tracked the environmental commitments associated with each site, enabling them to prove they had fulfilled obligations like preserving natural habitats.

As executives across industries recognize the business value of sustainable strategies like resilience and reduction, many construction firms are going beyond the letter of the law to embrace low-impact building philosophies. GIS apps that track the carbon footprint of building materials like cement and lumber can identify methods of reducing emissions before the first inch of foundation is laid.

Managing Operations—The Construction Phase

Once construction is underway, project managers need a single view of operations to maintain awareness of everything from construction materials to safety concerns.

A smart map that shows a site as a digital twin—complete with schedule and budget updates—is the ideal platform to keep planners, designers, architects, engineers, and other stakeholders informed.

The integration of drones with GIS has enabled a level of construction site monitoring that would have been unimaginable a generation ago. Images and video captured by drones supply a historical, top-down view of a site in progress. If a problem occurs, construction managers and architects can rewind to a previous building stage to determine the cause—collaborating on an authoritative project history.

Combining drone imagery with GIS has led to lifelike digital twins that mirror the relationships and behaviors of real-world systems. This helped the managers of one infrastructure project share schedules and drone imagery with project stakeholders and the public to earn their trust and keep them engaged during construction.

Spatial technology can also capture granular details that lead to a safer work environment. One construction firm used drones and GIS to measure material stockpiles, cutting 800 “working at risk” days by avoiding on-the-ground inspections, and saving £30,000 a year.

A digital twin with live sensor data provides another level of safety. If work is underway on an active bridge, sensors can alert managers when vibration exceeds threshold values—and map the precise location of the anomaly.

In the past, information from the construction site might have taken days to reach analysts or managers in the office—and may have come in the form of a handwritten document with information that was already outdated. Now, GIS apps enable workers to enter data through mobile devices on daily progress reports, quality inspections, or safety incidents, making that information instantly available to multiple stakeholders.

Location intelligence also helps construction managers weave sustainability into projects. Circular construction, which reduces waste by reusing or recycling materials, is becoming increasingly common. GIS technology helps track sources of waste and disposal locations, providing the operational intelligence to optimize supply chains and reduce visits to landfills.

Maintenance, Compliance, and Communication—The Postconstruction Phase

When a structure is complete, builders can lay down their tools—but for construction managers, some of the most important work lies ahead. Typically, 80 to 90 percent of an asset’s total cost of ownership is incurred during its operation. Location technology facilitates a handover process that ensures the owner understands how to operate the structure safely and efficiently.

Inspectors and technicians can use smart maps and GIS digital twins to direct repairs and perform maintenance. Centralizing building data in an accessible, spatially aware platform can reduce the time needed to address equipment breakdowns or malfunctions.

Communication is also important once a building or structure is in service. Web maps furnish residents, commuters, and employees with insight, whether that’s an accurate estimate of when a condominium’s air conditioning will be fixed or an update on carbon emissions saved from an office building’s sustainability features.

As the world’s aging infrastructure is exposed to a continually changing climate, the need for more sustainable, resilient structures grows more urgent. Location intelligence delivers the reliable data, streamlined workflows, enhanced safety, and collaborative workflows construction firms need to meet that demand.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

April 1, 2025 |

November 12, 2018 |

February 1, 2022 |

April 16, 2024 |