An electricity manhole is a little room buried in the street or sidewalk. It’s where utility workers access electric cables, switches, and other dangerous stuff. (In the old days, the majority of workers were men, so the term “manhole” stuck.)

When a cable fails, workers splice together new and old sections of the cable inside these manholes. Workers enter the manhole through a round entry, usually covered by—you guessed it—a heavy manhole cover.

Inside, manholes are hot, dangerous, and creepy. If a cable fails, it generates a lot of heat and sometimes fire. Any debris caught in the manhole will worsen the fire. And if things explode, those heavy manhole covers go flying.

To prevent problems like this, manholes should be inspected and cleaned of all debris. But since there are always a lot of other tasks to do—and, frankly, no one likes to inspect and clean manholes—this work often takes a backseat.

Not-So-Smart Inspection

I used to work at a power company that had 16,157 manholes in its service territory. Each one was numbered, from 1 to 16,157.

After encountering problems with the manholes—from clogged sump pumps to debris such as oil-soaked rags and dead leaves—we decided to get aggressive with manhole inspections and cleaning.

Where to begin? The logical way forward was to inspect the manholes in numerical order, starting with manhole no. 1. My company cooked up some fancy paper forms to do the inspection. But after a year of working through the process, we were hung up at around manhole no. 200. Instead of having actionable information in hand, we ended up with a stack of greasy, hard-to-read handwritten forms that needed to be entered into a database.

The company decided to abandon the ambitious project and move to as-needed inspections and cleaning. It was clear we were never going to inspect all 16,157 manholes, given our limited resources. Plus, most of the manholes were just fine. The real problem was knowing how to better target inspections.

Smart Answers for Smart Inspections

The trick to inspecting massive asset inventories such as manholes? Get smart.

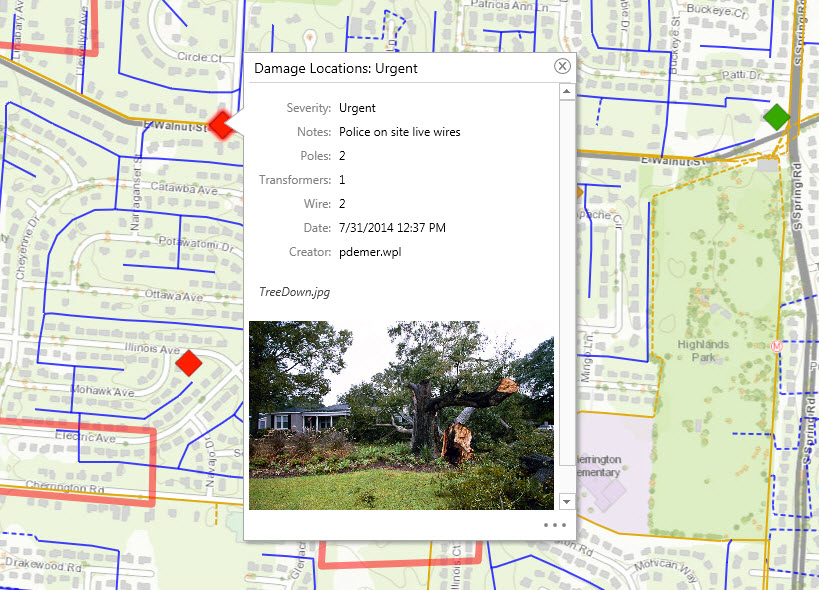

Figure out which assets are most vulnerable to something going wrong. Which manholes are near debris sources? Which manholes are most likely to be flooded? Which manholes carry critical cables? Which manholes have been vacant for years? Which manholes are apt to have a higher incidence of fires?

Esri’s GIS technology, the ArcGIS platform, helps answer these questions by leveraging utilities’ existing geospatial data. The platform makes the data available across the organization, on devices that staff commonly use, such as tablets and smartphones. And the best news—all this information sharing is done in a secure environment. If only I’d had this technology at my former company—we could have targeted the manholes that were most likely to have problems.

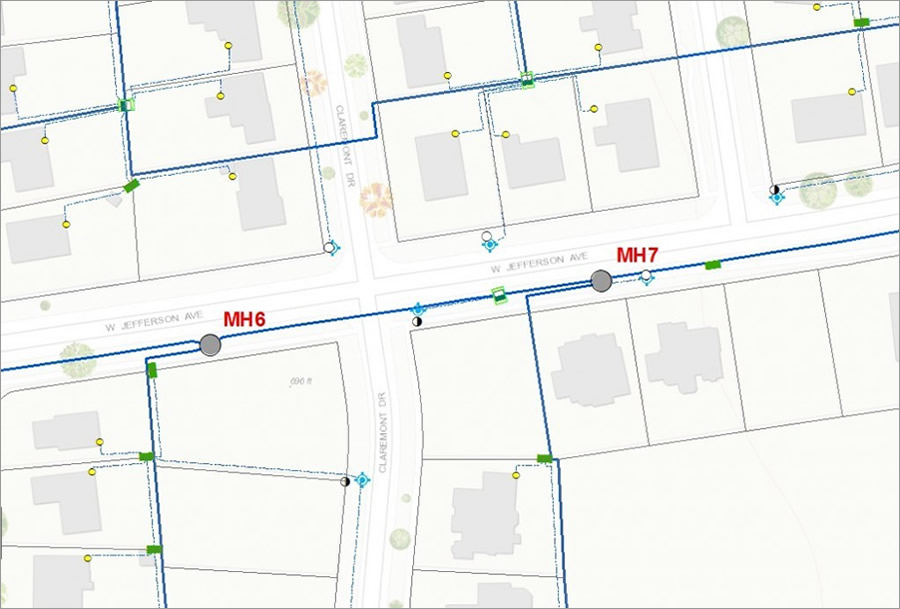

With GIS, you have the power to determine which of the thousands of your utility’s manholes need to be inspected and cleaned. You can cluster these manholes spatially on a map in your utility’s GIS. As a result, you can schedule inspections for minimal crew travel time, or you can combine inspections with other fieldwork that is happening nearby. Plus, you can easily import all kinds of content on the ArcGIS platform: weather, crime, graffiti incidents, abandoned buildings, high insurance risk, and any other types of spatial data. You can mash all this data together and focus on the manholes that are most likely to create a problem.

Organize, Inspect, and Report

Smart inspections include three simple steps: organize, inspect, and report.

Before you commence inspections at manhole no. 1, you need to organize. Organizing your data requires three key tasks: prioritizing, publishing, and sharing. To prioritize your inspections, start by identifying your assets based on geographic location and any special circumstances about these locations (such as areas that could be dangerous). Then publish your results for your organization so your operations department has a list of manholes to inspect. Finally, share your content with specific users within the organization. This gets the collaboration going.

The next step, inspect, is where utilities traditionally focus the majority of their time and often waste the most effort. Inspections include two tasks: locating and updating. First, locate the assets and then conduct the inspection. Finally, record and update the findings on your mobile device and sync the data back to the office via a dashboard.

The final step of the workflow is to report. Reports help utilities understand the status and priorities of work. To complete the reporting process, you need to monitor, analyze, and prioritize. Start by monitoring results coming from the field and analyzing these results to identify patterns and trends of facilities’ conditions. Using these insights, you can then prioritize the next day’s or week’s work by reviewing the status of activities and progress being made in the field.

That’s what smart inspection is all about—taking a huge number of assets to inspect and figuring out the best place to deploy limited resources in the field. Don’t organize the old way, by number or some old customary inspection cycle. Use smart inspection tactics, bringing in supporting data such as crime statistics, locations prone to flooding, and areas that have a history of problems.

This is what the ArcGIS platform does best: it delivers better execution of the tasks you have been doing for years. How? By giving you the ability to access data from across the organization. ArcGIS makes it a snap to use data from outside the company—data that utilities typically don’t manage. And best of all, ArcGIS gives you the ability to answer the question, where is my biggest problem? by using spatial analysis.

Get started with ArcGIS for inspections and surveys by watching the free, 60-minute Esri training seminar Utility Asset Inspection Using ArcGIS. Get more information on GIS for utilities. Explore ready-to-use ArcGIS mobile solution templates for utilities.