Industrial and manufacturing companies are required to monitor groundwater conditions at sites that have a history of contamination. Monitoring may include measuring depth to water, recording parameters collected in the field and collecting samples for submission to a laboratory. Typically, periodic monitoring is conducted to meet site-specific state or federal monitoring requirements. Wells are installed close to facility operational areas to monitor groundwater as part of efforts to determine compliance with water quality standards.

Industrial and manufacturing companies with groundwater monitoring requirements often contract with engineering firms like Kennedy Jenks to conduct monitoring efforts. Kennedy Jenks manages several sites across the US where field staff routinely sample groundwater and collect water quality data. Kennedy Jenks uses a common set of protocols to perform groundwater monitoring. The protocols include capturing the depth of water, documenting well conditions, recording geochemical properties (e.g., temperature, pH, and turbidity), and collecting samples to send to a laboratory for analysis.

The data collected helps track how well the water quality complies with standards, and it measures progress toward meeting standards after implementing best management practices and remedial options.

Challenge

Traditional monitoring efforts relied on paper-based forms to record water quality data during field inspections. This method was not only time-consuming but also prone to errors and inefficiencies. Field staff had to manually record data such as inspection details, well information, date and time the data was collected, and water quality parameters, sometimes in challenging weather conditions. After returning to the office, this data had to be laboriously transcribed into spreadsheets or databases, and photos taken on smartphones needed to be matched with the correct well and notations.

Partner

Kennedy Jenks is a leading water and environmental engineering firm. An Esri Silver partner, the employee-owned organization specializes in providing innovative design, construction and technology solutions for water and industrial projects throughout the Unites States.

Solution

Beginning in the fall of 2021, Kennedy Jenks initiated a transformative shift toward digital forms as the firm migrated to ArcGIS Enterprise. These digital forms were customized to suit the specific requirements of staff’s work in the field. Unlike the paper forms, the digital format offered an intuitive and user-friendly interface with selectable drill-down fields, allowing field staff to navigate from general data views to specific ones effortlessly.

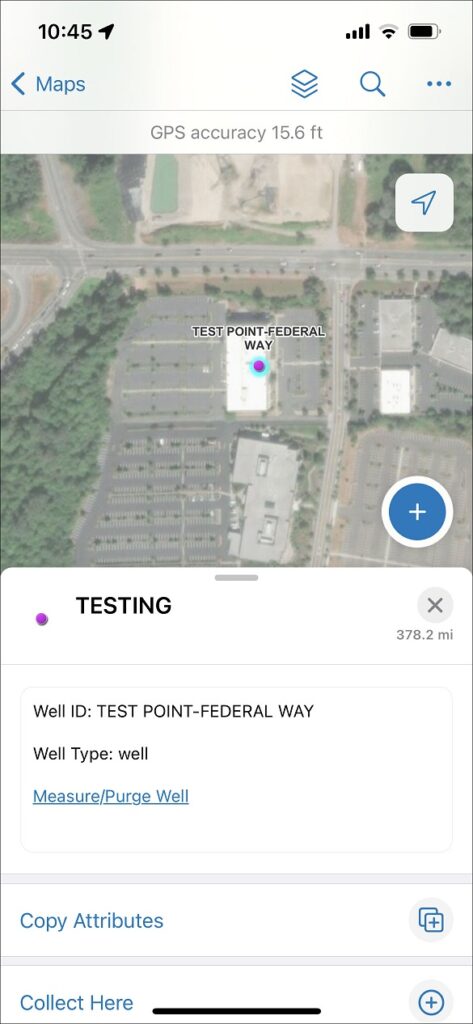

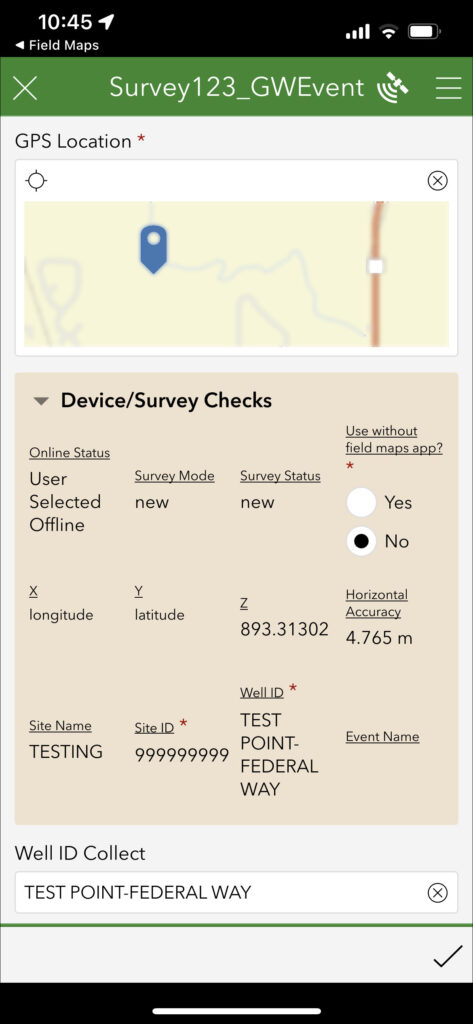

Field personnel could attach tables related to the site, guiding the types of samples required. Using the ArcGIS Field Maps app, staff could easily locate the well they were inspecting and click on the ArcGIS Survey123 link to generate a form with autopopulated, location-specific data, reducing data entry errors. Importantly, the digital forms were designed to be used offline, ensuring functionality even in areas with limited connectivity.

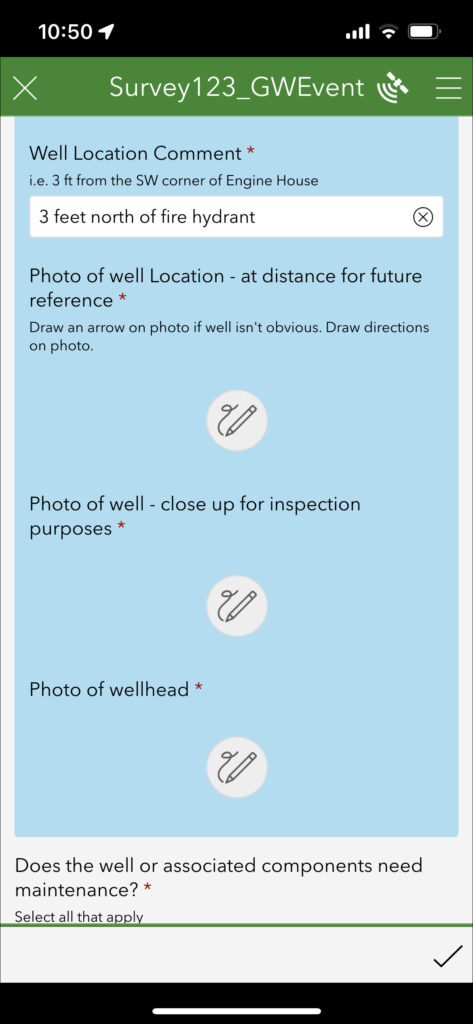

To enhance data richness, project managers requested the ability to attach photos of well locations and make notes directly on the photos, all of which seamlessly integrated into the database.

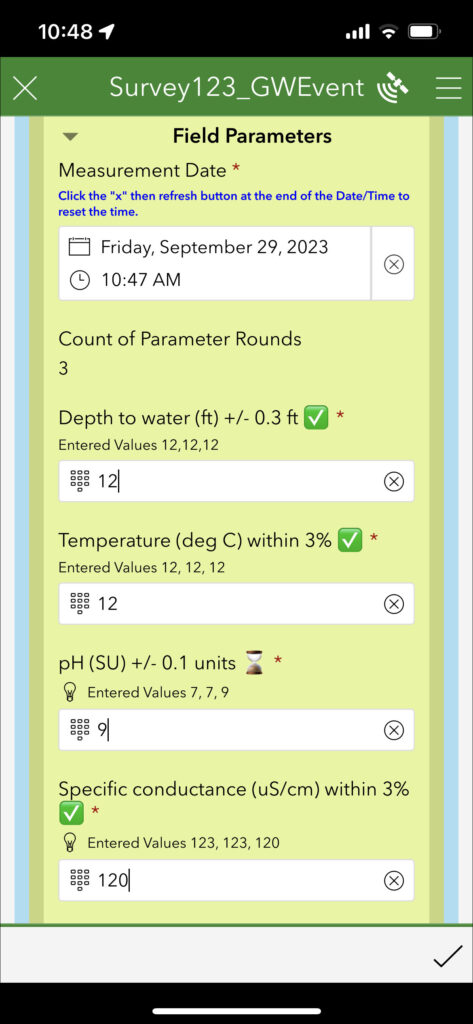

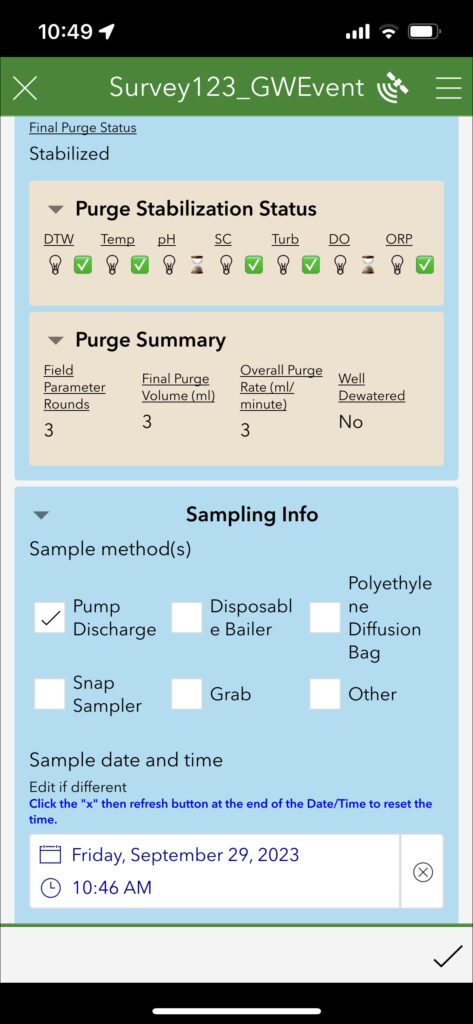

When wells were purged for sampling, the digital forms facilitated comprehensive data entry, including the instruments used, purging methods, and tubing specifications. Parameters are recorded at regular intervals until stability is reached.

An icon-based cue for parameter stability was included in ArcGIS Survey123 to remove the need for manual calculations.

The digital forms also addressed historical data needs. Field staff could access previous monitoring data, including the date of the most recent visit, depth to water, and depth to contaminants like light nonaqueous phase liquids (LNAPL), aiding in determining whether new entries are consistent with previous data.

Results

Digital forms made it easier to check the data quality in the office. Users could now easily flag wells that needed maintenance or had performance issues. Staff could determine if the data met the regulatory requirements, helping managers plan more effectively for repairs and future efforts. The data became instantly accessible, enhancing communication between field staff and project managers.

A visually appealing dashboard was created to let users see the most important information with a quick look. The dashboard provided real-time insights into monitoring results and inspection status. This feature allowed project managers to address issues promptly, eliminating the need for costly return visits to sites. In addition to the dashboard, digital PDF versions of the forms are routed automatically to the project team for use in reports after data submission. Field staff were trained virtually, given their nationwide distribution, with digital documentation and PDFs for reference.

Kennedy Jenks has introduced digital forms to its clients and continues to encourage its field staff to embrace this technology, further advancing the efficiency and accuracy of water quality assessments and informed decision-making.

Kennedy Jenks’s adoption of digital forms has transformed the firm’s water quality assessment process, ensuring compliance with environmental regulations and delivering valuable benefits in terms of data accuracy, accessibility, and real-time decision-making.

Learn more about location intelligence for AEC:

GIS for Architecture, Engineering, and Construction

Stay Connected with Esri’s AEC Team:

Subscribe to the AEC industry newsletter “Esri News for AEC”.

Join the Architecture, Engineering and Construction Community