In 2021 the US Environmental Protection Agency (EPA) revised the requirements of the Lead and Copper Rule to better protect our communities from the risks of lead exposure. The Lead and Copper Rule Revisions (LCRR) are focused on protecting our children and removing lead from our drinking water systems.

The LCRR requires water systems to prepare and maintain an inventory of service line materials by October 16, 2024. In addition, any water system that has inventoried a lead service line, galvanized requiring replacement, or lead status unknown service line in its distribution system must submit to the state a lead service line replacement plan. Water systems are also required to share this information with the public and update their inventory at least annually until they have demonstrated that they have met the requirements.

EPA Guidance

In August 2022, the EPA released the Guidance for Developing and Maintaining a Service Line Inventory document to support water systems with their efforts to develop inventories and provide states with needed information for oversight and reporting to EPA. This document provides essential information to help water systems comply with the requirement to prepare and maintain an inventory of service line materials by October 16, 2024. Specifically, the EPA’s lead service line inventory guidance provides the following:

- Best practices for inventory development and communicating information to the public

- A template for water systems, states, and tribes to use or adapt to create their inventory.

- Case studies on developing, reviewing, and communicating about inventories

- Highlights the importance of prioritizing inventory development in disadvantaged communities where children live and play

Tackling an Immense Project

The 2023 EPA Drinking Water Infrastructure Needs Survey and Assessment estimates that there are more than 9 million lead service lines and 2.8 million stand-alone galvanized service lines in the United States. Performing an inventory to identify where there is lead and meeting the requirements of the LCRR is overwhelming for many water service providers. Initially, performing an inventory may sound simple, but it can be complicated. Many questions need to be answered when preparing to perform an inventory and create a replacement plan. Some of the questions I’ve discussed with water utilities include (but are not limited to) the following:

- Does my state require more than the EPA?

- What historical records can be used to start my inventory?

- Can customers help by gathering information for the inventory?

- Do I need to partner with a third party?

- Can I use geographic information system (GIS) technology to help meet the LCRR requirements?

Does my state require more than the EPA?

This isn’t always an easy question to answer. In California where I live, the State Water Resources Control Board, through the Division of Drinking Water (DDW), enforces the California Lead and Copper Rule, which is aligned with the EPA’s Lead and Copper Rule. In response to the LCRR, the DDW released an inventory template (spreadsheet) that contains the minimum amount of information required for water systems to comply with the LCRR’s initial lead service line inventory.

Although the inventory template provides guidance on what data needs to be provided to the state, it does not identify how the data may be different from what is on the EPA template. For example, in CA, the state wants to know if material other than lead was used in the past. In addition, water systems are not required to use the template. They may choose to create a custom spreadsheet, database, or map.

Although the data requirements may be understood, there are still uncertainties about how to perform the inventory. According to the DDW, lead service lines are not common in California. Many water providers believe that they have no lead or very little lead in their system and prefer to use statistical verification to complete their inventory. The approved method of statistical verification is the 95 percent confidence level interval approach. This approach is impacted by how well you understand your data and how you evaluate the data. It can play a significant role in determining what percentage of service lines need to be physically verified. This is where working with your state representative will help.

Several methods of material identification are approved by the state on a case-by-case basis: water quality sampling, predictive models, interpolation (statistical verification is under this category), interviews, and emerging technology. The best way to understand what your state requires and if the work you are doing will be accepted is to collaborate with your regional Water Resource Control engineer.

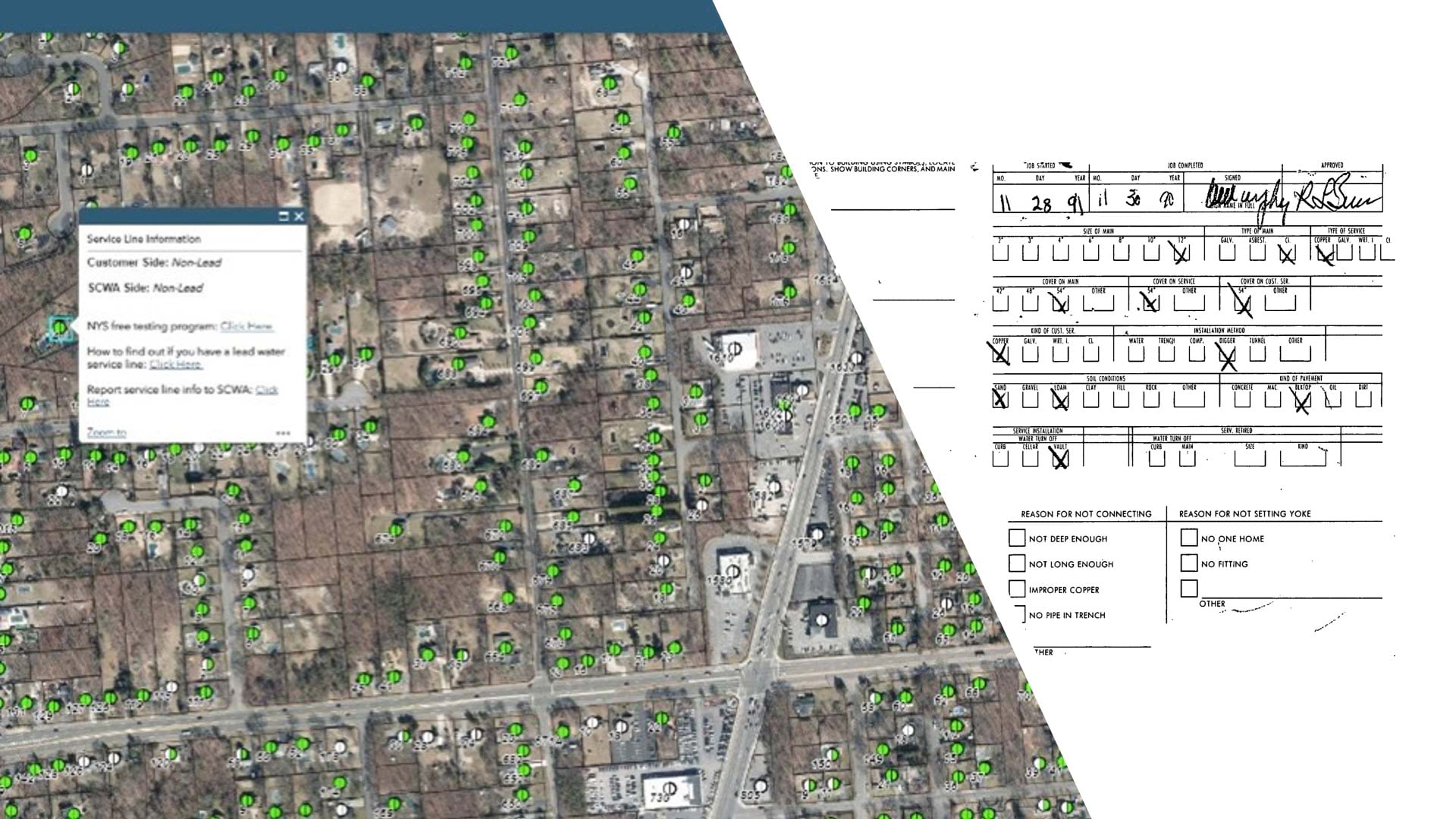

What historical records can be used to start my inventory?

Various historical records can be reviewed to create an initial inventory. Previous evaluation of materials performed in response to the regulatory revisions to the National Primary Drinking Water Regulation in the 1980s and the 1991 Lead and Copper Rule can be a good place to start. Construction records, plumbing codes, and permits can be used to identify materials used to connect to the distribution system. In addition, tap cards, system maps and drawings, water main replacement records, meter installation records, capital improvement plans, inspection records, water loss studies, and annual reports can be used.

Although historical records can provide a starting point for your inventory, keep in mind that they may be inaccurate and unreliable. They may not reflect changes made in the system. Service line material that is uncertain should be listed as “unknown.” The results of reviewing all available records will guide you in the next step to investigate service lines of unknown material.

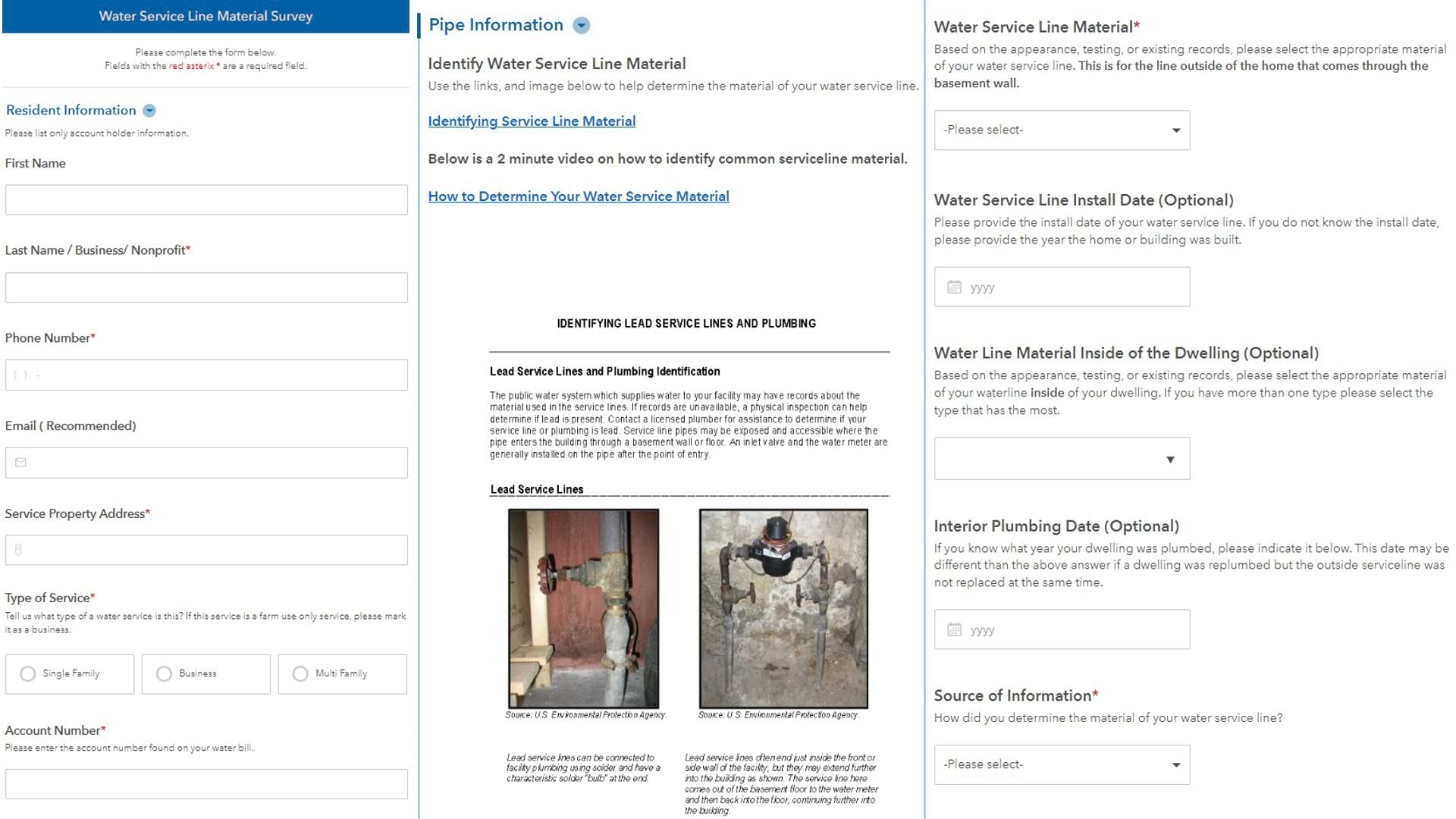

Can customers help by gathering information for the inventory?

Many utilities have turned to the public for help in identifying the material on the customer-owned portion of the service line. To do this successfully, the utility should start by educating its customers. Customers may not know where to start. They don’t know the best place to access their service line. If the water meter is in the basement, the service line may be visible where it comes into the building and connects to the meter. If the meter pit is in the sidewalk or yard, it may be harder for the customer to locate where the service line enters their house. Utilities should provide guidance on the most probable scenario for their service area.

In addition to locating the service line, customers will need to understand how to identify service line material. Utilities have various methods for guiding customers through this step. They often ask customers to perform a scratch test and upload pictures. A magnet test can be used to confirm service line material (a magnet will not stick to lead). These methods can be provided in a pamphlet mailed to customers, shared via the utility website, or even shown in an instructional video. Data collected by the customer can be gathered using a web form, a mobile app, or paper surveys. I don’t recommend using paper surveys as they result in additional work for utility staff.

Having customers participate in the service line inventory not only educates the customer about the work being done to remove lead from the water system but also provides important information to the utility.

Do I need to partner with a third party?

The EPA encourages water systems to build partnerships that will support them in completing their service line inventory. For example, third parties such as plumbers, building inspectors, and public health departments may be able to provide service line material information based on their work. Community-based organizations, universities, and homeowner associations can be strong partners when educating and engaging your customers. Technology providers and consultants can be strong partners as well, providing digital solutions and services.

An evaluation of existing technology and staff should be done to determine the best use of resources. Supplementing staff and growing technology-based solutions should be done strategically to get the best results.

Can I use GIS to help meet the LCRR requirements?

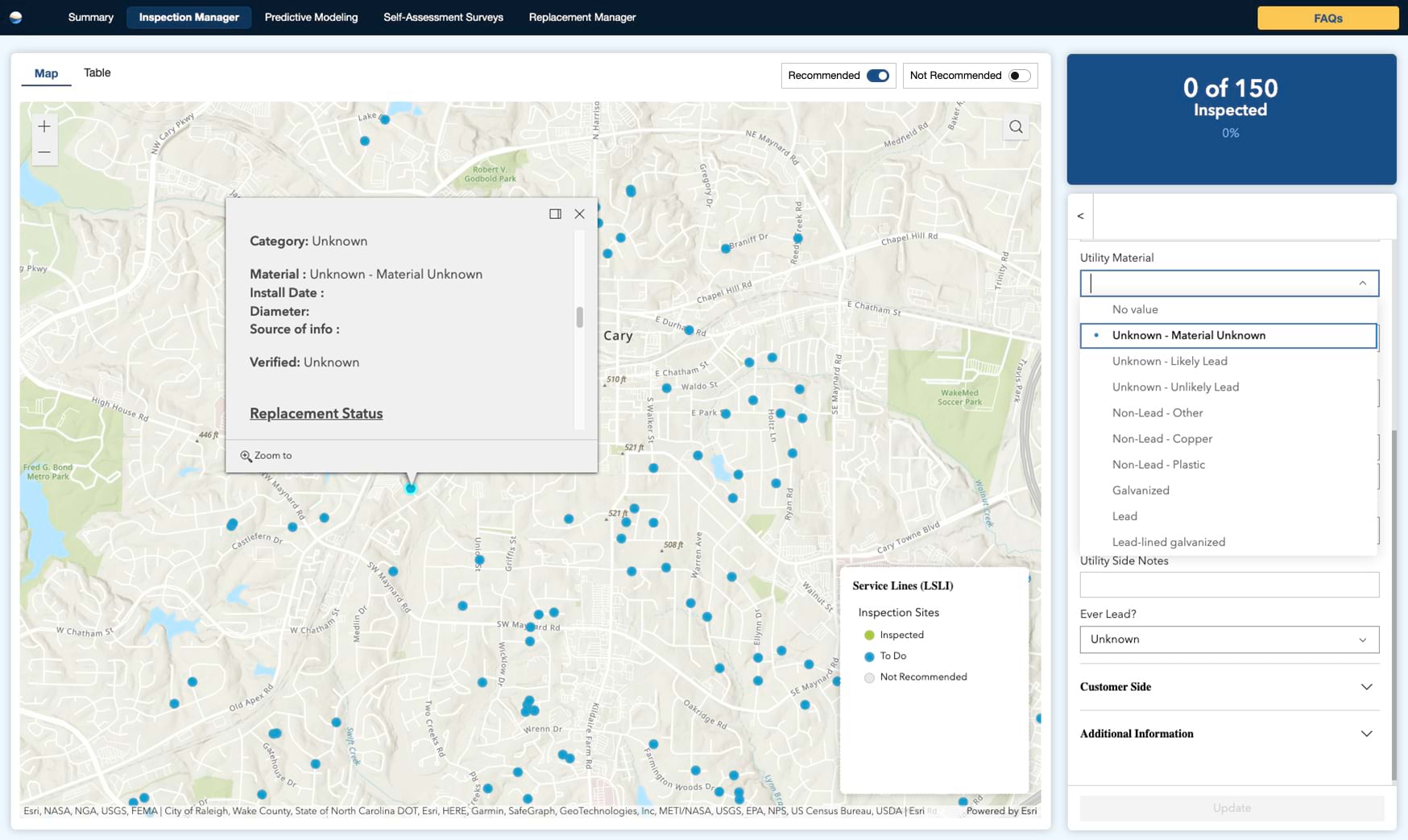

Yes, GIS can help streamline the work you are doing to meet the LCRR requirements.

Initially, GIS can be used to integrate disparate data types and perform analytics. Analysis can be used to identify gaps and discrepancies in your data. As you add and improve data, analytics can be used to prioritize field verification of material type. Data can be viewed spatially and sorted into categories enabling organizations to pinpoint areas that are likely to have lead.

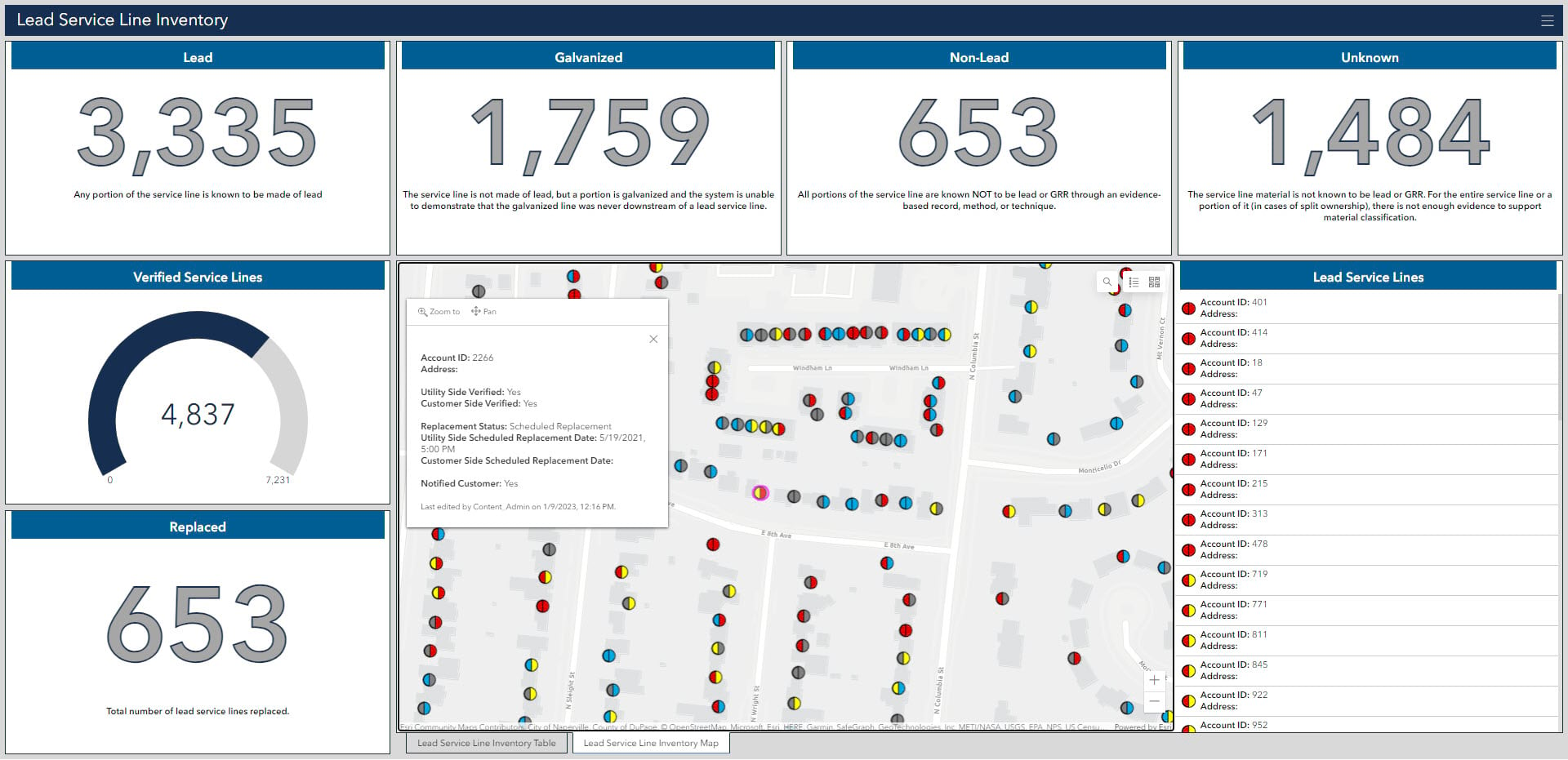

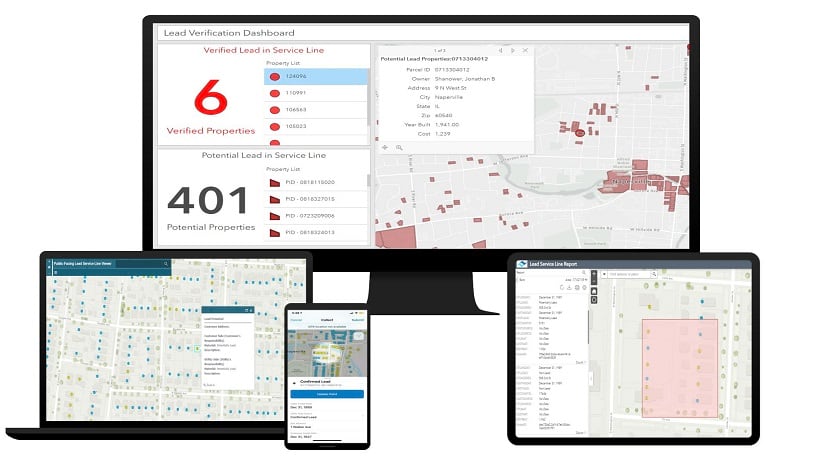

In addition to the powerful analytics that GIS provides, in response to the EPA’s Lead and Copper Rule Revisions, Esri developed the Lead Service Line Inventory solution. This solution delivers a set of capabilities that help utilities to

- Streamline service line inventory.

- Validate service line material in the field.

- Monitor replacement activities and optimize replacement programs.

- Share information with the public.

The Lead Service Line Inventory solution is updated as Esri experts learn more about the LCRR requirements and how to best help utilities meet these requirements. The solution is supported by Esri’s technical support team and, the best part, it’s free for our customers to download, configure, and start using.

If you have questions about Esri’s Lead Service Line Inventory solution please don’t hesitate to contact us, water@esri.com.

Article Discussion: