When one link in a supply chain breaks unexpectedly, executives with visibility into the entire network excel at launching backup plans to minimize disruption and protect sales. For those without supply chain visibility, desperation can set in quickly.

That happened this summer when one business seeking a new supplier of refined sunflower oil emailed a Georgia farm, as reported by Civil Eats. The business requested 50,000 metric tons per month, but the farm’s average output fell a bit short: 34 metric tons a year.

Until recently, Ukraine had been a go-to exporter of sunflower oil, which is used as cooking oil and in packaged foods and cosmetics. Russia’s invasion of Ukraine has sent companies scrambling for alternate supplies.

When the unexpected occurs—whether it’s a war, a natural disaster, or a pandemic—manufacturers, distributors, and retailers must pivot with remarkable speed. Today’s supply chain executives have discovered they need more than inventory management solutions geared toward stocking warehouse shelves.

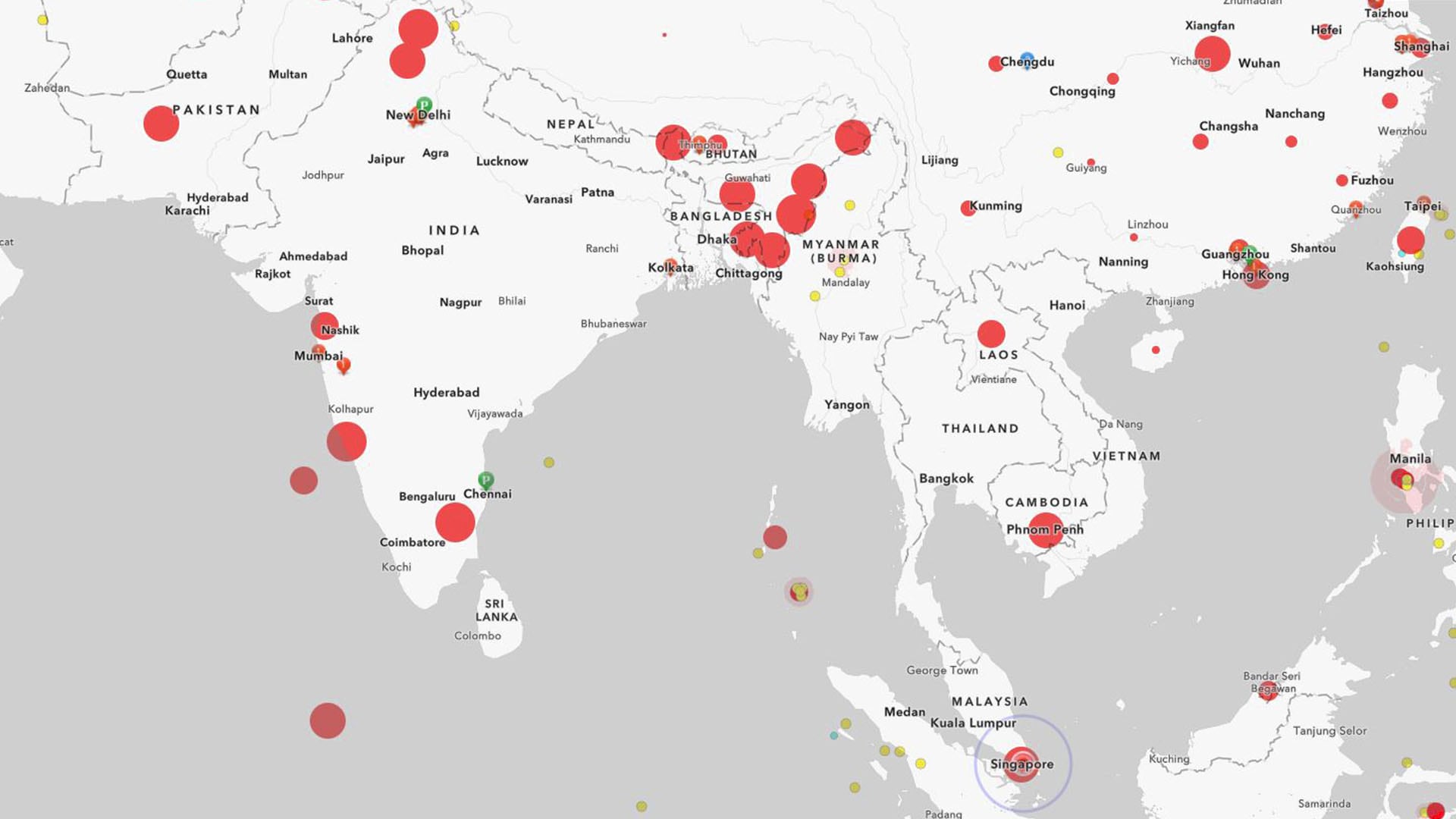

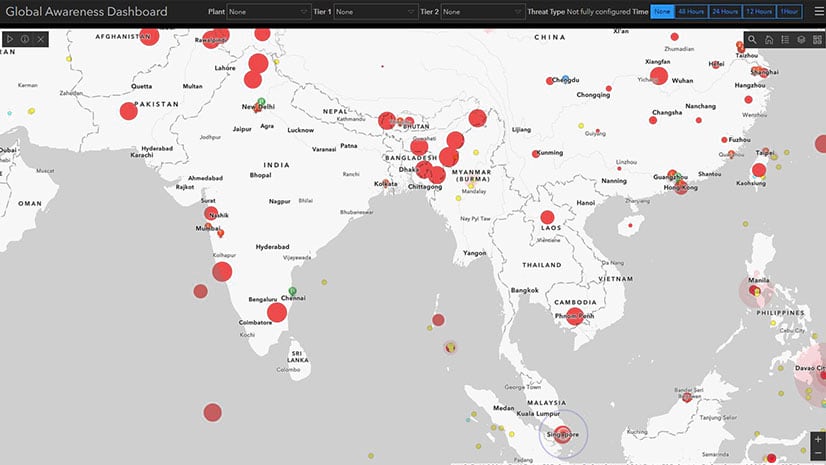

Those who stay ahead of supply chain disruptions use geographic information system (GIS) technology to see where materials and finished goods are in the supply chain, and test trade-offs between factors such as suppliers, costs, speed to market, and net-zero goals.

Mapping Every Step toward Supply Chain Visibility

Supply chain visibility has been key to overcoming recent disruptions. But a logistics strategy grounded in visibility isn’t just about navigating extreme moments; it also helps executives deliver products to market under calmer circumstances.

Speaking at a recent supply chain industry conference, one pharmaceuticals executive stressed the importance of mapping all phases of a company’s supply chain, from planning to procurement, manufacturing to distribution.

Only when executives have a clear picture of each supply link can they effectively manage their network, according to McKinsey. The consulting firm says three practices are key to avoiding supply chain disruptions: visibility, scenario planning, and comprehensive, reliable data.

Global leaders in manufacturing, distribution, and retail use GIS technology for all three.

A Complex Picture, Simplified

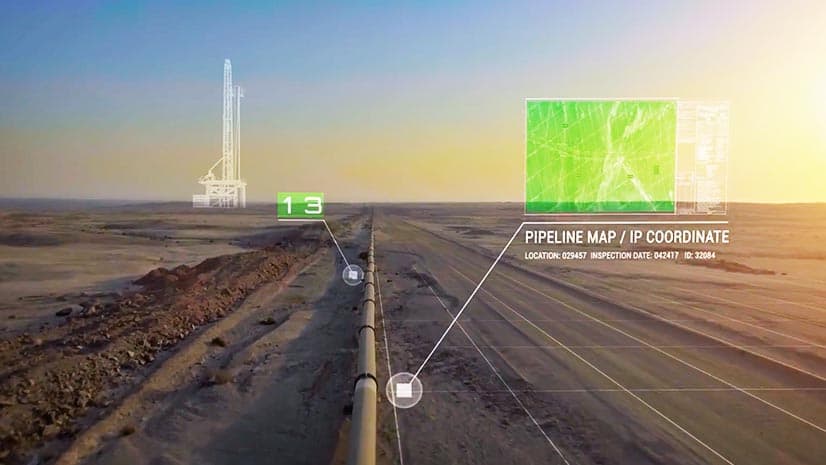

GIS acts as a single source of truth for locations throughout the supply chain—showing shipping routes, distribution centers, and supplier facilities across every stage of production. GIS treats each as an information layer that executives can toggle on or off on smart maps, creating the visibility needed to understand complex global relationships.

When unexpected events occur—or even before they do—planners use the technology to run what-if scenarios, weighing the outcomes of changing a route, a supplier, or a strategy. The data science behind those GIS simulations is called GeoAI–or geospatial artificial intelligence. As Esri’s Wendy Keyes explained in a recent WhereNext Think Tank:

We set up a GeoAI model to focus on a particular goal—that could be minimizing emissions, maximizing equity, or minimizing weather risk. Then we define the other factors involved—customer satisfaction, revenue, profit, etc. This is where the power of simulation comes in. . . . We’re not predicting the future yet, but we are getting much better at anticipating outcomes and making better decisions based on that insight.

GeoAI can be used in tandem with another GIS technique that displays complex supply chain relationships in intuitive knowledge trees. Such visuals help business leaders understand how an event’s effect on one supply tier will ripple to others. Seeing that information in a geographic context can illuminate key dependencies among suppliers and strengthen contingency plans.

No matter how the next disruption develops, companies that manage supply chain data in GIS will be prepared. With that foundation, executives can visualize critical links and plan effectively by modeling scenarios before taking decisive action.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

April 1, 2025 |

November 12, 2018 |

April 16, 2024 |

February 1, 2022 |