The COVID-19 pandemic may have diverted attention from other global issues, but a recent survey found that at least one remains prominent in consumers’ minds. In a survey of more than 10,000 people in the US and Europe, the Carbon Trust found that two out of three shoppers support the use of carbon labeling. A carbon label is a display mark on products from companies committed to measuring and reducing carbon emissions to slow climate change.

Fielded in February and March, the online survey included participants from the US, UK, and eight Western European countries. While 67 percent of respondents favor carbon labels, just 22 percent said they think about a product’s carbon footprint when making purchases, indicating they would like to be better informed.

Despite growing popularity of the “buy local” movement, most products still arrive at stores and doorsteps from hundreds or thousands of miles away, often through a complicated series of supply chain handoffs. Measuring the carbon emissions connected to a product’s raw materials, its harvesting, processing, and transport is a location-intensive, data-heavy exercise. But consumers indicate it’s one they want manufacturers to undertake.

Answering to Conscientious Buyers

Carbon emissions make up the vast majority of greenhouse gas emissions, which scientists say warm the planet and lead to higher sea levels and more extreme weather events.

With or without regulations to prompt them, business leaders have begun to embrace sustainable products and processes as part of corporate social responsibility initiatives—in many cases answering to a more activist buying public. Brands known for environment-first policies form the vanguard—think Patagonia and Seventh Generation. But nearly every household brand now has a plan for carbon mitigation:

- Coca-Cola intends to cut its carbon footprint by a quarter by 2025.

- A decade ago, Ford said it would take 15 years to reduce carbon emissions by 30 percent; the automaker achieved that mark in half the time.

- BP recently pledged to be a net zero company by 2050, and is shifting its energy portfolio toward large investments in renewable, low-carbon energy.

A Complex Tracking Problem with a Burgeoning Business Benefit

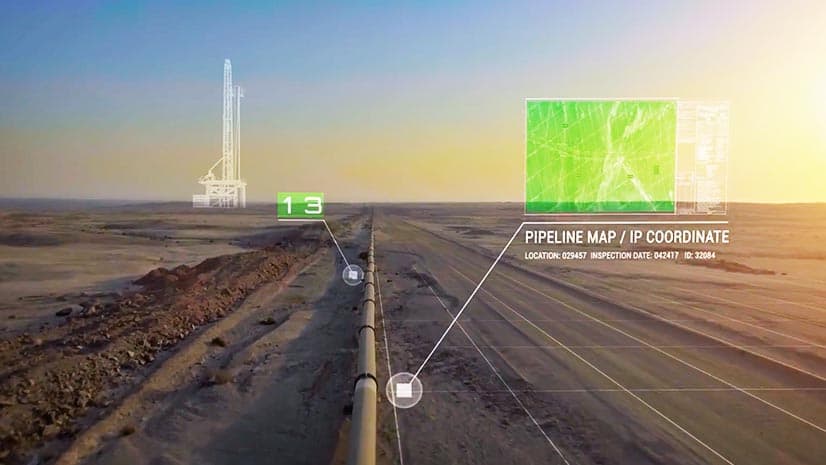

Tracking a product’s carbon footprint is a challenge even for the savviest digital company. Emissions come from every stage of production, including the heavy equipment that mines component metals, the supplier factories that produce subassemblies and finished goods, and the ocean freighters and delivery trucks that ensure their arrival.

Monitoring that chain of events hasn’t been a forte for global businesses, and the COVID-19 crisis reminded us how opaque global supply chains can be. Pandemic, wildfire, or typhoon, disruptions tend to be harsh reminders of how intricate and uncharted much of the supply chain is.

And yet, companies with a business motive to create visibility have done so. FedEx tracks the movement and provenance of millions of packages every day. GM mapped the locations of not just tier 1 suppliers, but the companies who supply them; the automaker understands supply chain risk better as a result, and can recover faster from disruption.

Those and other leading companies use digital technology to collect troves of supply chain data, organizing and converting it into useful insight that fuels daily operations. Often, geography is the canvas those companies use to make key decisions, and geographic information system (GIS) technology is a tool of choice.

Now the Carbon Trust survey reveals a growing business incentive for companies to track their carbon footprint across the supply chain, and many will turn to that same location technology for clarity.

The process of strengthening a company against outside disruptions begins with the same technique used to track a carbon footprint—mapping the supply chain.

A New Addition to the Cost-Benefit Equation

The expense of creating supply chain visibility is not insignificant. It involves hours of work gathering information on the supply chain and capturing it in a location-centric system like GIS. The investment tends to be front loaded, and often pays off in myriad ways—from increased agility when disruptions occur, to better visibility of and control over a brand’s carbon output.

Yet, disruptions to the supply chain can cost millions. In a 2018 study, the Business Continuity Institute and Zurich Insurance found that 12 percent of companies suffered financial losses of €250,001 to €500,000 from supply chain disruptions, while 8 percent lost €1 million to €10 million. Six percent of companies lost even more.

The Carbon Trust survey suggests that companies should consider reputational damage, too—and perhaps lost sales—if they fail to account for their carbon footprint across the supply chain.

With buyers worldwide showing greater interest in the origins of products they support, business leaders may find a new and beneficial use for the geographic analysis they’ve done on their supply chains.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

November 12, 2018 |

April 1, 2025 |

April 29, 2025 |

February 1, 2022 |