Years ago, business executives greeted new enterprise technology with open arms, won over by promises of faster operations, connected teams, and reduced costs.

For some, those promises dissolved into a series of costly and complicated implementations.

In one of the world’s great agricultural regions, a bioenergy company has defied the odds and achieved the original vision, increasing business security and generating cost savings with an enterprise technology called a geographic information system (GIS).

The History of the Fields

A generation ago, the vast sugarcane plantations of Brazil were cut manually, with fire used as a management tool.

Today, roughly 95 percent of Brazil’s sugarcane harvest is mechanized. Harvesters and their embedded technology increase crop yields while reducing worker health and safety risks and impacts on the environment. The innovation has fueled the country’s rise as a global agtech leader and one of the world’s most productive food pantries.

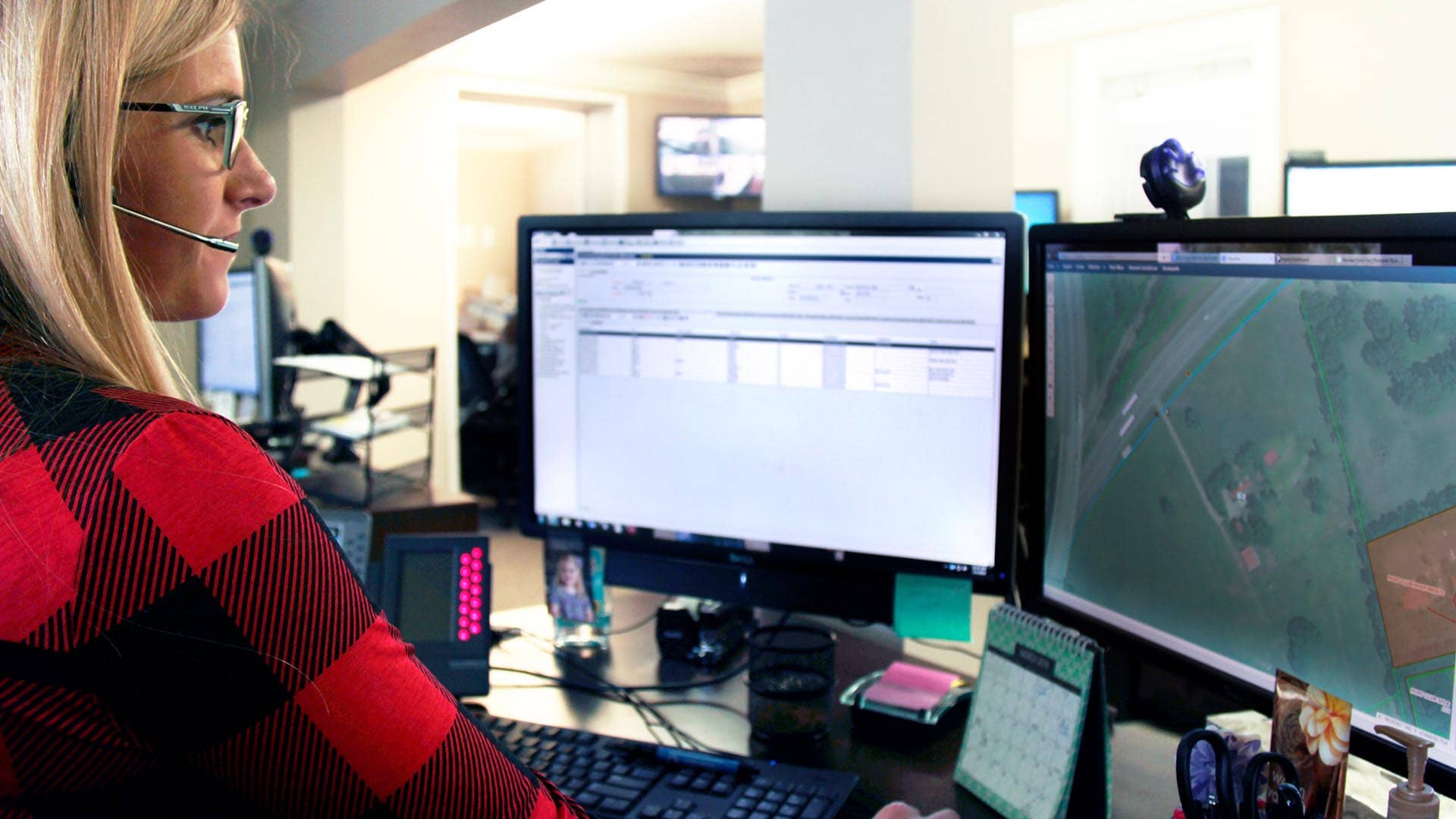

For bp bioenergy, a pillar of Brazil’s booming sugarcane economy, GIS-generated location intelligence is an engine of efficiency. Across the enterprise, GIS has improved outcomes by increasing the safety and speed of operations.

Finding New Efficiencies

bp bioenergy manages thousands of hectares of arable land, which enables the company to produce up to 1.7 million tons of sugar per harvest, in addition to 1.7 million liters of ethanol and 1,400 gigawatt hours of electricity. Across five Brazilian states, with 11 agro-industrial units, the company uses location technology to identify opportunities for improvements to boost its efficiency.

“We are a company that operates on a large scale and we need to continue improving and innovating as much as possible, to optimize processes and costs and increase our efficiency, which are essential elements to stay in business,” says Miguel Prieto, GIS coordinator at bp bioenergy.

With GIS, you can certify that everything is going well with the operation.

How Location Insights Transformed Large-Scale Agriculture

Location technology now supports 23 distinct applications across the enterprise at bp bioenergy. GIS-based innovations have generated savings across the enterprise, but it all began with a friendly challenge between two colleagues.

Carlos Mondio, coordinator of agro-industrial controls, who has worked for the company for 16 years, oversees the Moema unit, one of bp bioenergy’s largest production regions. Among other duties, Mondio coordinates the payments of the contractors who carry out the crop treatments in the sugarcane fields. In the past, the company relied on these suppliers to report that jobs were completed correctly.

But as the scale of operations grew, so did the need for a centralized system to monitor costs and streamline the contracting process. Mondio asked Prieto if he could create a more efficient way of authenticating third-party work.

“How could I say no to such a challenge?” Prieto recounts.

Using GIS to track the routes of sensor-equipped tractors and planes, Mondio and team verified the movements of the third-party providers. With the accountability gained through location awareness, they’ve reduced operational costs by 7 percent.

GIS is the concrete evidence of what really happened in the field.

High-Precision Farming, Guided by GIS

Before long, another colleague came knocking on Prieto’s door with a task that is at the heart of bp bioenergy’s operations: optimizing the harvest.

Harvesting sugarcane involves a carousel of movement. A harvester travels down a length of field, cutting cane billets and feeding the crop into the empty bed of an attached tractor or truck. When the truck is full, the harvester detaches from it and picks up an empty truck, while the full one is transported to the mill and unloaded.

When this cycle is multiplied across hundreds of crews and fields, delays, and wasted movement can pile up. For Mário Salani Junior, a mechanization manager at bp bioenergy, this was a process ripe for innovation. He reached out to Prieto, and within a week, the GIS coordinator had developed a pilot solution.

Using sophisticated analytics, the GIS app improves routing and positioning of tractors, making the harvest faster and more efficient. Planners can predetermine the ideal entrance and exit areas for harvesters and identify the best transfer points for sugarcane loads, eliminating wasted time and motion. “With this technology, you prove that these are the best decisions,” Salani says.

Location insights along with other innovations have helped bp bioenergy decrease costs while increasing efficiency. Since 2019, the number of harvesters required to do the same work has dropped to 120 from 223, while the tons of sugarcane harvested per day rose to 985 from 580.

With the routing efficiency introduced by location technology, the company was also able to reduce fuel consumption and therefore emissions. It’s a trend seen in other industries as well: By streamlining truck deliveries or service routes with GIS, emissions and costs fall while efficiency increases.

It’s a technology we can really apply in our processes day-by-day … to be more safe, reduce the costs, and be more efficient.

Rising Demand for Spatial Context Across the Enterprise

As the value of GIS gained recognition at bp bioenergy, new opportunities for location solutions arose across the enterprise. Location technology supports worker safety, for instance, by showing emergency responders the quickest routes in case of field incidents.

That’s just one benefit of mapping the thousands of miles of private roads that crisscross the company’s properties. At bp bioenergy, the geometry of over 34,000 sugarcane fields changes on a near-daily basis as new areas are added or harvest cycles conclude. In the past, these changes were tracked manually, one at a time.

Now, GIS maps update the dimensions of cropland in real time, aiding decision-making throughout the enterprise. “They need to know precisely the area every day to make payments, do planning, to know how much they’ll be harvesting, how much fertilizer they’re buying, how many plants,” Mondio explains.

With the years ahead predicted to bring even greater growth in Brazil’s agriculture sector, bp bioenergy is positioned to unlock even greater value across the enterprise through GIS.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

November 25, 2024 |

February 25, 2025 |

November 12, 2018 |

April 1, 2025 |