With apologies to Texas, most things are bigger in New York City. The Big Apple hosts the tallest skyscraper in the Western Hemisphere. It boasts the world’s most valuable sports market. And it manages the largest transit system in the United States. With nearly 9 million bus and train riders every weekday, NYC’s system is more than 10 times the size of America’s second largest, Chicago.

Stretching through New York City’s five boroughs and the surrounding suburbs, the transportation system encompasses hundreds of miles of track, more than 12,000 buses and train cars, and a staggering $1 trillion in hard assets. Those assets range from the signals embedded in tracks to the tracks themselves, along with the bridges and tunnels that form the system’s arteries.

Managing Assets at Scale

For someone who manages $1 trillion worth of assets, Sean Fitzpatrick doesn’t seem ruffled. When the director of enterprise asset management for New York’s Metropolitan Transit Authority (MTA) sits down with WhereNext to discuss the challenges facing the New York subway, he begins with a simple concept. “There’s a huge onus on the MTA to run 24/7,” Fitzpatrick explains. (If subway riders could chime in, they might add, “run flawlessly.”)

Only a few subway systems in the world operate around the clock, every day of the week. Most of those that do shut down overnight devote the time to maintenance work. The MTA has no such luxury.

Perhaps it’s a New Yorker’s gumption that keeps Fitzpatrick calm in the face of such responsibility. But it doesn’t hurt that the MTA has a vision for better managing its vast portfolio of assets. Or that it is beginning to master the tools—including location intelligence technologies—to make it happen.

We have a huge infrastructure, and much of it is 70 to 100 years old. But at the same time, we are tasked with keeping up with the capacity that keeps increasing.

Billions of Riders to Accommodate

Ridership has declined slightly in the past two years, but the long-term story of the New York City subway is one of growth. The numbers rose from 966 million in 1975 to more than 1.7 billion in 2017. All the while, the subway itself barely changed. In the past eight decades, New York has not added a single major train line. The upshot isn’t hard to imagine. In 2016, the number of subway delays blamed on overcrowding was four times what it was in 2012.

In recognition of those conditions, the MTA had been working for years toward better asset management. In one of the world’s largest subway systems, it’s no small feat to understand where every asset is located, let alone keep each one in working order to ensure that millions of hard-to-please New Yorkers can crisscross the city every day.

A recent series of high-profile stumbles, including a train derailment, delays, and repeated power outages, prompted then-New York governor Andrew Cuomo, putative head of the MTA, to declare a state of emergency for the subway. In issuing the notice, Cuomo gave the MTA two directives: immediately address the subway’s most egregious problems, and create a long-term plan to bolster the system’s capability.

Billions to Spend—With a Catch

Most executives would give up their company parking spot for a spending account the size of the MTA’s. But few would sign on for the challenges that accompany the $30 billion allotment, Fitzpatrick says.

“Even though our budget sounds big, when you’re talking about $1 trillion in assets, it’s limited in what it can accomplish in a system as large and complex as ours. We have to make sure we’re spending money in the right way.”

When assets broke down, the MTA’s traditional approach was to mount up, assembling a crew of trade workers including:

- A safety team to monitor the work and communicate with a subway control center

- Signal electrical engineers

- Track mechanical engineers

- Track electrical engineers

The workers were costly and often difficult to coordinate. The break-fix routine was papering over the system’s ills and draining the MTA’s budget.

“When you fix something after it has broken, it’s three to four times more expensive as opposed to having done something either preventatively or predictably,” Fitzpatrick notes. “So, we’re on a journey to move from reactive to preventative to predictive, ultimately.”

As part of that shift—and in response to the governor’s mandate—the MTA committed to mustering work teams more efficiently, deploying them to work sites with precision, and helping them accomplish more while they’re together. To do that, managers and work crews needed location intelligence.

Addressing Repeat Offenders

At the heart of the governor’s state of emergency is the system of signals and switches that safely guide trains through tunnels and between stations. Anyone who has ridden a subway more than once has probably experienced it: The train stops in a darkened tunnel, and the conductor announces, “We’re waiting on a signal to proceed; we hope to be moving shortly.”

Those delays can be the product of normal traffic, but in New York City they often stemmed from a defect in a signaling system long past its prime. In fact, some of the subway’s tunnels, tracks, equipment, and stations are 70 to 100 years old, and some of its electrical cables are sheathed in cloth.

“One of the things that we did almost immediately was we started to use GIS technology to map where the defects were occurring, both in the signals and on the track side,” Fitzpatrick says.

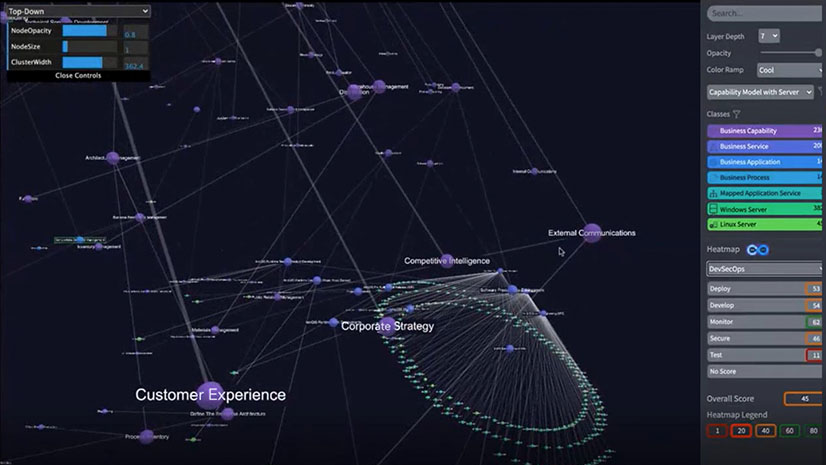

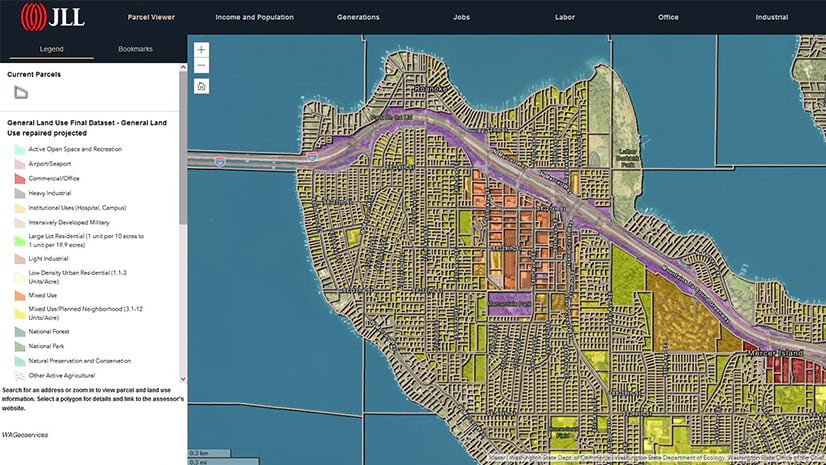

A GIS, or geographic information system, delivers location intelligence to a range of industries, creating smart maps that analyze data associated with a location: a balky subway signal, a retailer’s same-store sales growth, even the status of planes in transit. Forward-leaning companies are using the technology for asset management in office environments—tracking which conference rooms get the most use and how often maintenance issues interfere with business operations.

For Fitzpatrick and the MTA, the location intelligence gained from GIS revealed opportunities for efficiency they had been missing.

“We were able to see very quickly that there were certain signals and certain sections of track where we were having recurring issues within a very short period of time—days [or] weeks where things were repeatedly breaking down.”

Location Intelligence Yields Action

Once the MTA mapped defects in its signal system, managers moved to better coordinate the repair work itself, including where and how it was performed. They created a GIS-based mobile app for joint switch inspections—the jobs that require teams of skilled craft people.

Now when a manager requests a signal repair, all members of the crew receive a work order on their mobile device. Through an integration with the MTA’s logistics system, it’s clear when the needed materials will arrive on the job site. That, Fitzpatrick says, cuts down on guesswork that had become too common.

“We can actually say, ‘The material is going to show up on Tuesday, so we’ll have the team converge there Tuesday afternoon,’ rather than [saying], ‘Well, the material is going to show up maybe Thursday. So why don’t you schedule it Saturday because it will probably be there by then.’”

With the mobile app, the MTA has also begun to shift from reactive to proactive asset management. For example, a crew manager can use GIS capabilities to find other signals and switches in the vicinity of a scheduled repair. If a similar switch is nearby, the team can perform preventative maintenance while they’re down there, Fitzpatrick says. “There’s a logistical benefit to that, too.”

At the center of it all is the location intelligence that shows managers where and when the work needs to happen. That spatiotemporal understanding, in GIS parlance, is helping to modernize the MTA’s asset management at a critical moment.

The app has already helped cut the time required for joint switch inspections almost in half. That has helped create “tremendous savings” in costs and improved subway uptime, Fitzpatrick says.

To maintain the subway system in a 24/7 fashion, we have to employ smart technology. Geospatial technology—GIS–is critical to that.

An Ongoing Digital Transformation

While location intelligence technology helps the MTA log short-term improvements, it’s also fueling long-term plans. Already, the agency has taken its digital transformation to the sky, using drones to perform inspections of above-ground rails—an efficiency gain over “walking the tracks.”

Underground, track-geometry cars roll through the tunnels like IoT demonstration pods, outfitted with sensors that collect data on track curvature, temperature, moisture, and other physical conditions. The sensor data is fed into the GIS, which logs the location of those measurements, helping managers identify anomalies. But with fewer than 10 specialized cars and more than 600 miles of track to cover, inspections take longer than executives would like.

So the MTA is working with makers of rolling stock, as subway cars are known in the business, to equip passenger trains with those same sensors for more frequent inspections.

“Feeding that into GIS, we can then look at those [assets] spatially to figure out not just the condition of the track, but are there certain curves where we experience more issues than others?” Fitzpatrick says. Safety inspectors will analyze, for instance, whether certain levels of wear boost the likelihood of derailment on a particular section of track, and whether a slight change in the curvature might reduce that risk. “We’re using GIS to analyze all of that,” Fitzpatrick says.

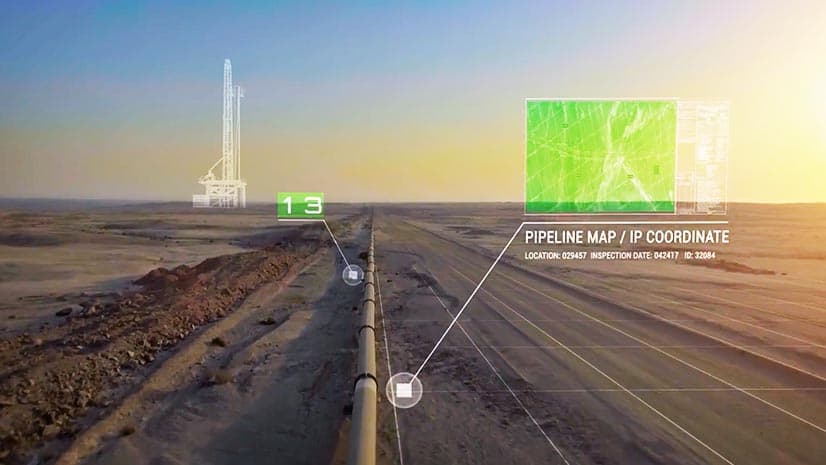

The MTA wants to use the same technology to create a digital twin of its assets—a virtual 3D map showing infrastructure locations and conditions. If that digital twin were projected onto mobile device screens or augmented reality headsets, MTA work crews, for example, could “see” through the pavement for a bird’s-eye view of tunnels, tracks, signals, and utility infrastructure affecting the maintenance work they need to perform.

That kind of thinking puts the New York MTA in the vanguard of innovative organizations. A water utility in New Jersey, for instance, was one of the first in the world to project a digital twin of infrastructure on augmented reality goggles, feeding its work crews real-time location intelligence. Meanwhile, the largest port in Europe is pursuing its own digital twin vision to prepare for the arrival of autonomous ships.

Whether it’s a smart city, a pioneering port, or one of the largest subway systems in the world, leading organizations are using the power of location intelligence technologies to drive efficiencies, manage risk, capture business opportunities, and make smarter decisions.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

November 12, 2018 |

February 1, 2022 |

July 29, 2025 |

July 14, 2025 |