Before you break ground, break a few pixels.

That’s the design philosophy blooming among architects, engineers, and construction firms. Projects traditionally began with 2D designs, moved to 3D physical mockups, and then became real-world infrastructure. With that came real-world hassles. But now structures worldwide are being built and contextualized digitally first.

To the delight of project accountants, planners, and those who will occupy the structures themselves, new technology is shaking up the process of translating 2D designs into 3D reality.

The Situation—A High Cost for Poor Planning

The wisdom of the tailor—measure twice, cut once—also applies to architects, engineers, property developers, construction firms, and others in the building trades. In fact, the amount of time dedicated to planning a property or infrastructure project affects how well it meets the customer’s vision, achieves safety standards, and stays within budget and schedule.

In a 2017 report, a UK-based group dedicated to driving errors out of construction found that the industry lost £21 billion—or 21 percent of its annual revenue—to what sports fans might call unforced errors. The culprits: late design changes, ineffective communication, and poor coordination.

Researchers found that project plans often lacked context that could show how a new building would impact the land and structures around it, and how those structures and land would impact the building.

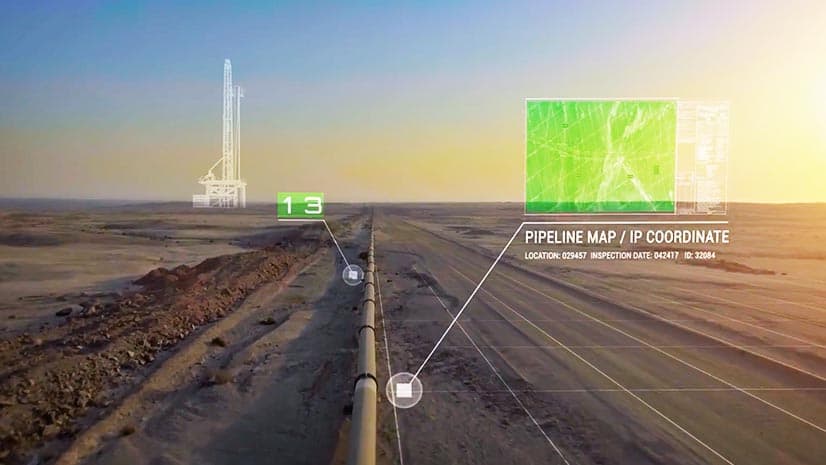

A new pairing of technologies is doing just that—helping planners see relationships between the built environment and planned structures. With that vision, they can plan for contingencies and avoid surprises during construction.

The NextTech—A Unique, Combined Perspective

Designers and planners have long sought tools to visualize before they build. Some cities, for instance, have created physical scale models that show all the buildings within city limits. But those models don’t reveal things like underground utilities or a building’s interior spaces, and they can’t be updated quickly as conditions change and buildings come and go.

In the greater London area, a joint venture of Skanska, Costain, and STRABAG is designing a high-speed rail line in a unique way. In what is likely a first in the UK architecture, engineering, and construction (AEC) industry, the partners are planning this £2.1 billion rail project with a combination of 3D technologies—BIM (building information modeling) and GIS (geographic information system).

GIS helps stakeholders see the project modeled with interrelationships such as terrain and structures around the rail line, including underground utilities. BIM provides a detailed 3D view of the structure being built. With the combined tools, planners can see a 3D model in context before they break ground—which can prevent rework and cost overruns.

It’s a technique that holds promise for infrastructure projects and residential developments alike. 3D modeling technologies are now the digital sandbox that allows planners to “stand” in a location and see a proposed project from any angle, within the environment it will inhabit. Thus situated, designers and stakeholders can see the internal and external context of buildings during the idea stage.

The 3D modeling tools are beginning to crop up in projects from simple housing developments to massive infrastructure works like the London rail line. The video below shows how BIM and GIS deliver a simplified illustration of a planned residential development in Lofoten, Norway, an archipelago north of the Arctic Circle. The slides were developed by Norwegian architects Boxs Arkitektstudio.

As the video shows, GIS and BIM create a twinned perspective—a view of the inside of the building as well as its environs. That gives planners the small-scale insight needed to design desirable living spaces and present them to stakeholders. It also reveals the birds-eye perspective that helps planners gauge whether the buildings are situated appropriately within the town.

The Upshot—Foresight Yields Savings

When early planning mistakes materialize during later phases of construction, project costs tend to increase significantly. For instance, when the Wisconsin DOT analyzed a long-term highway interchange project in Milwaukee to determine the savings it could have achieved had planners used 3D modeling, the estimate came to nearly $10 million.

In contrast, mistakes in the digital world are free—or nearly so. Recognizing that, global destinations such as London, Singapore, and Boston are going 3D, investing in digital replicas of their cities to speed up project assessments, streamline the permitting process, ensure citizens’ quality of life, and enforce regulations.

Through the marriage of BIM and GIS, today’s architects, engineers, and construction managers are virtually iterating and collaborating on 3D digital models, seeing projects with a level of foresight they have not previously enjoyed.

With that vision, they can quickly see what is right—and what could go wrong—with any project.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

April 1, 2025 |

November 12, 2018 |

April 16, 2024 |

February 1, 2022 |