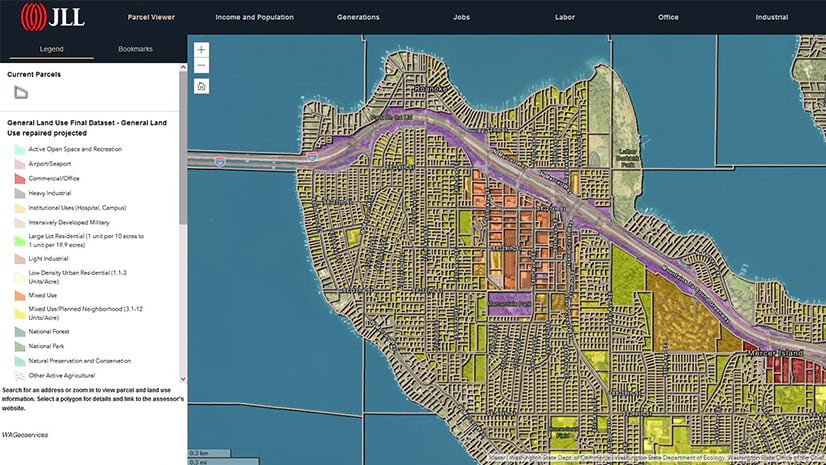

UPS saves hundreds of millions of dollars each year from a system called ORION. Used on nearly all the company’s 55,000 North American delivery routes, ORION relies on algorithms, a geographic information system (GIS), and smart mapping to efficiently route each driver through his or her day—sometimes in ways that are counterintuitive even to delivery veterans. In addition to its bottom-line impact, the system saves UPS 100 million miles of driving each year, equivalent to approximately 100,000 metric tons of carbon dioxide emissions.

UPS senior director of process management Jack Levis, the system’s original champion, sat down with WhereNext to discuss the corporate culture that nurtured the idea, the next wave of change in a fast-moving logistics world, why innovations aren’t always as innovative as they seem, and the danger behind buzzwords. Plus he offers a challenge for business executives bent on process improvement: change your employees’ morning conversations.

WhereNext: Let’s start with your high-level view of ORION. It’s a pretty innovative system.

Levis: Today, I think people will look at ORION and go, Boy, is that innovative. But it’s not. I mean, what does it take to say, I want to optimize a driver’s route? People have been talking about that for 30, 40, 50 years. We didn’t create the concept of the traveling salesman problem. We didn’t create the concept of a map. So conceptually, is that innovative? No. It’s innovative because it worked, not because the idea is brilliant. So if you want to be innovative, make sure your innovation is going to work.

Deployment was about double the effort of building the system—creating the algorithms and the tools . . . because you've got to make 50,000 drivers use it.

WhereNext: ORION took 10 years to realize. That kind of timeline demands patience from the C-suite and perseverance from the people implementing it. What kind of company supports an initiative like that?

Levis: We’re a quantitative company and a constant improvement company; that’s the culture of UPS. In the year 2000, when most people had flip phones, we deployed a handheld that had Wi-Fi, a color screen, Bluetooth, an IrDA port, and GPS. In the late ’90s, when we were very profitable and known as the most efficient company, our leaders said, “This isn’t good enough. We need to move down this path of analytics, take information out of people’s heads, put it into databases, and build a data model.”

Our C-suite is incredibly supportive of these things, and we’re fortunate that they have this type of vision. That [level of] forward thinking is exciting to me, and I’m proud to be one of the thousands of UPSers who have made it successful.

Continual Innovation

WhereNext: The logistics industry moves fast. Now that you’ve deployed ORION, how do you ensure it remains on the cutting edge?

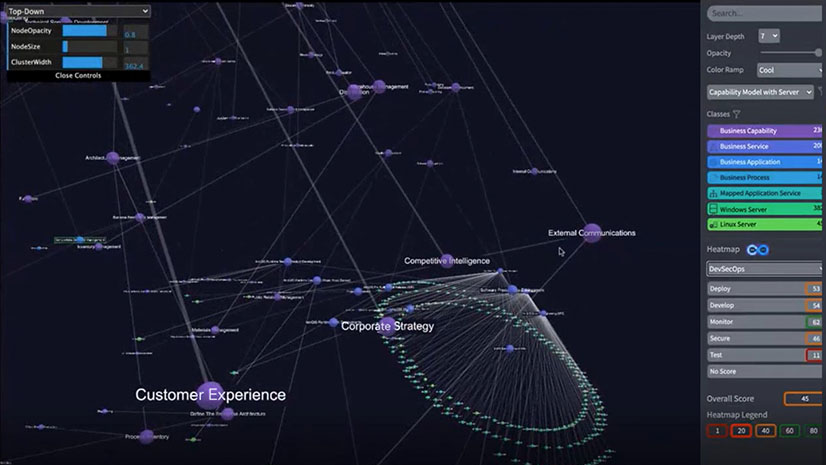

Levis: ORION is optimizing a piece of final-mile delivery—only a piece of it. We’ve seen gains, but there’s more to do. Today, a human decides which vehicle and which driver delivers each package. There’s no reason ORION can’t decide that, so we’re working on that.

We’re also working on dynamic optimization. Today, when a driver leaves the building, the order of deliveries never changes. We achieved all these gains with something that’s static, so we’re going to move into a dynamic world so that ORION will update during the day. It may detect that the driver is ahead or behind schedule and say, Let me reoptimize the route. Or the change could come because a customer says, I need you to make a pickup. The system says, Here’s the next move—this is where you should go. But it’ll do it knowing that it can insert that inside everything else you need to do.

WhereNext: What about innovation beyond delivery routes?

Levis: ORION is only a little portion of our business—final-mile. There’s an ORION waiting in the wings for city-to-city movement. It will decide things like, Which trailer should your package go into? Which driver should pull the trailer? Where should that be sorted? So we’ll have a city-to-city optimization to keep us effective—again, in real time.

Inside the building, if we’re sorting packages, the system will analyze, How many people do we need? Where should [the packages] be sorted? Where should vehicles be parked? How should vehicles be washed?

Once you’ve optimized final-mile, city-to-city, and inside the building, you’ve optimized the entire network. That’s what we’re looking to do. And it’s not really on the road map yet, but we also have an airline, and I’m guessing the airline optimization will come.

Changing Conversations

WhereNext: What were the phases of ORION’s evolution?

Levis: It took a number of years to build and test the algorithms and a number of years to build the systems around it. From my estimate, deployment was about double the effort of building the system. It was about double because you’ve got to make 50,000 drivers use it.

WhereNext: That’s a change management process. What did you learn from it?

Levis: What we learned was, if you build it, don’t assume they’re going to come. You go out and deploy a site, and while you’re deploying it, maybe the drivers are getting gains. But if in the morning the drivers are talking about the same things they always did before you got there, you became a flavor of the month. Trust me. They’re appeasing you, but their conversations are what they always were. You have to change the morning conversation.

WhereNext: How did you do that?

Levis: We did that through communication, through top-down support, but also by changing metrics. Drivers aren’t measured on how much money they saved. They’re measured on things they can control. Did you maintain your map? Are you overriding the system? Are you following the solution?

In theory, if you did all of these leading-indicator things, the lagging indicator of money saved, how can that not happen? So they’re measured on what they do, what they can control. The lagging indicator of dollars saved is just a measurement for corporate.

It's innovative because it worked, not because the idea is brilliant. So if you want to be innovative, make sure your innovation is going to work.

Our drivers and managers used to think a 1 percent gain in route efficiency was awesome. Now they’re sometimes seeing 10 percent. That starts changing conversations. And then that change becomes infectious and everybody else says, Well, I can do it, too.

That changes behavior, and so does communication and support from the top. That’s how we did it.

Data, Buzzwords, and Hidden Dimensions

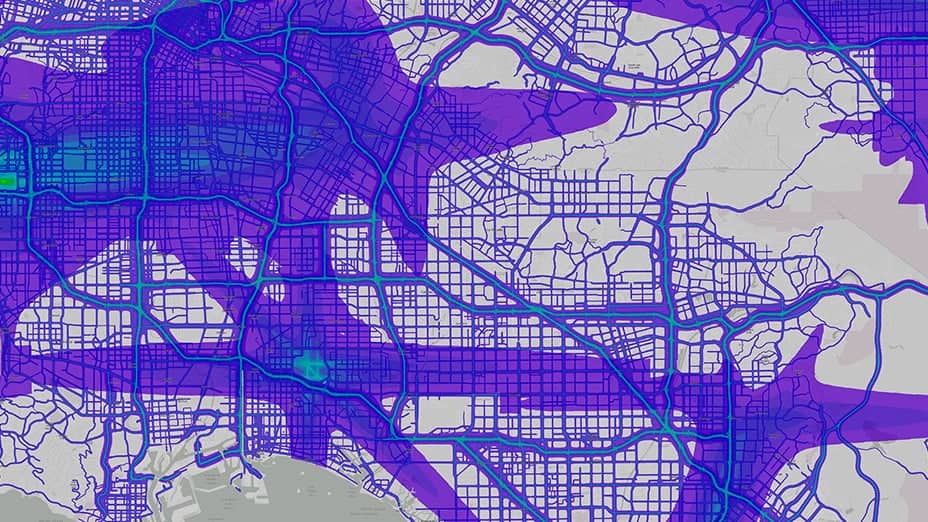

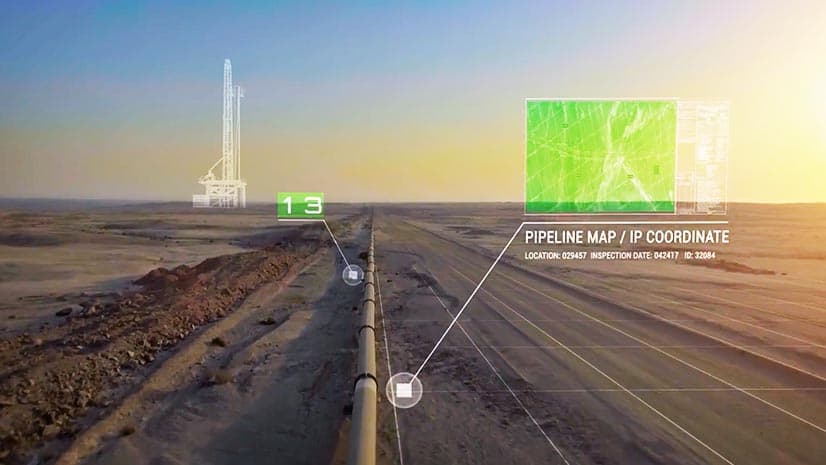

WhereNext: Understanding where exactly to deliver a package and how to move efficiently through a route are some of ORION’s core skills, and GIS technology helps create those skills. But GIS also helps UPS plan the timing of its routes, which can be just as important. Can you talk about the impact of time?

Levis: One of the problems with looking at a map is [that] you can see two dimensions, but it’s hard to see the third dimension, and that third dimension is time. The optimization needs to take time into account—not just where the delivery is, but what time you’re going to be there.

ORION will do things that are very counterintuitive to us because of things like time. It thinks differently than people; that’s why you need the temporal aspect. ORION may have you drive right past three deliveries. Drivers hate that. But ORION thinks about the whole day, so it may have you drive right past these deliveries because it says the time that you would take to make them in the morning is offset by other inefficiencies later. The system will live with this inefficiency now because it brings something better later. Humans just can’t think through that.

WhereNext: A lot of business executives are clamoring for a system that will save their company millions of dollars every year. What’s your advice to them?

Levis: Focus on the most important decisions; that’s it. Stop listening to the buzzwords. It’s a pet peeve of mine. We’re going to use big data to do A, B, C. But what’s the decision? And how do you know big data is the solution to the decision? Maybe the solution to the decision is just a simple Excel spreadsheet.

Focus on the decision and work backward, and all the garbage goes away. Focus on the what and let the how surface itself.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

November 12, 2018 |

February 1, 2022 |

July 29, 2025 |

July 14, 2025 |