Manufacturing could be heading toward a renaissance in North America as international logistics delays and supply chain disruptions persist. But in the face of domestic labor shortages and high inflation, business leaders intent on boosting local capacity are focused on how to do so cost effectively.

Some are discovering a new level of efficiency from indoor location intelligence. With smart maps to visualize and analyze operations, decision-makers can understand where further optimization is possible.

Managing Automated Operations with a Map

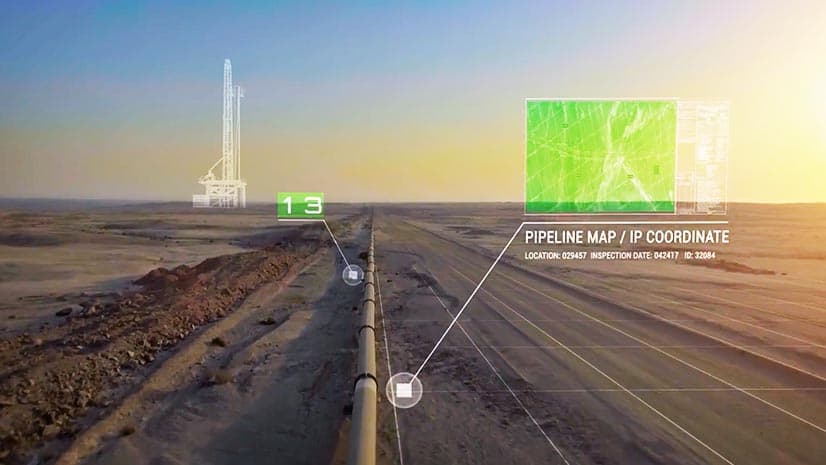

For years, suppliers, manufacturers, distributors, and logistics providers alike have invested in automation tech—including AI-based programs, IoT sensors, and robots—to boost operational efficiency on factory and warehouse floors.

Introducing new technologies and automation to a workstream adds new operational complexities. Smarter systems often mean more equipment to manage without more humans to do the monitoring. Operational leaders will need to keep production processes running smoothly by staying ahead of maintenance, catching system failures early, and spotting opportunities for process improvements.

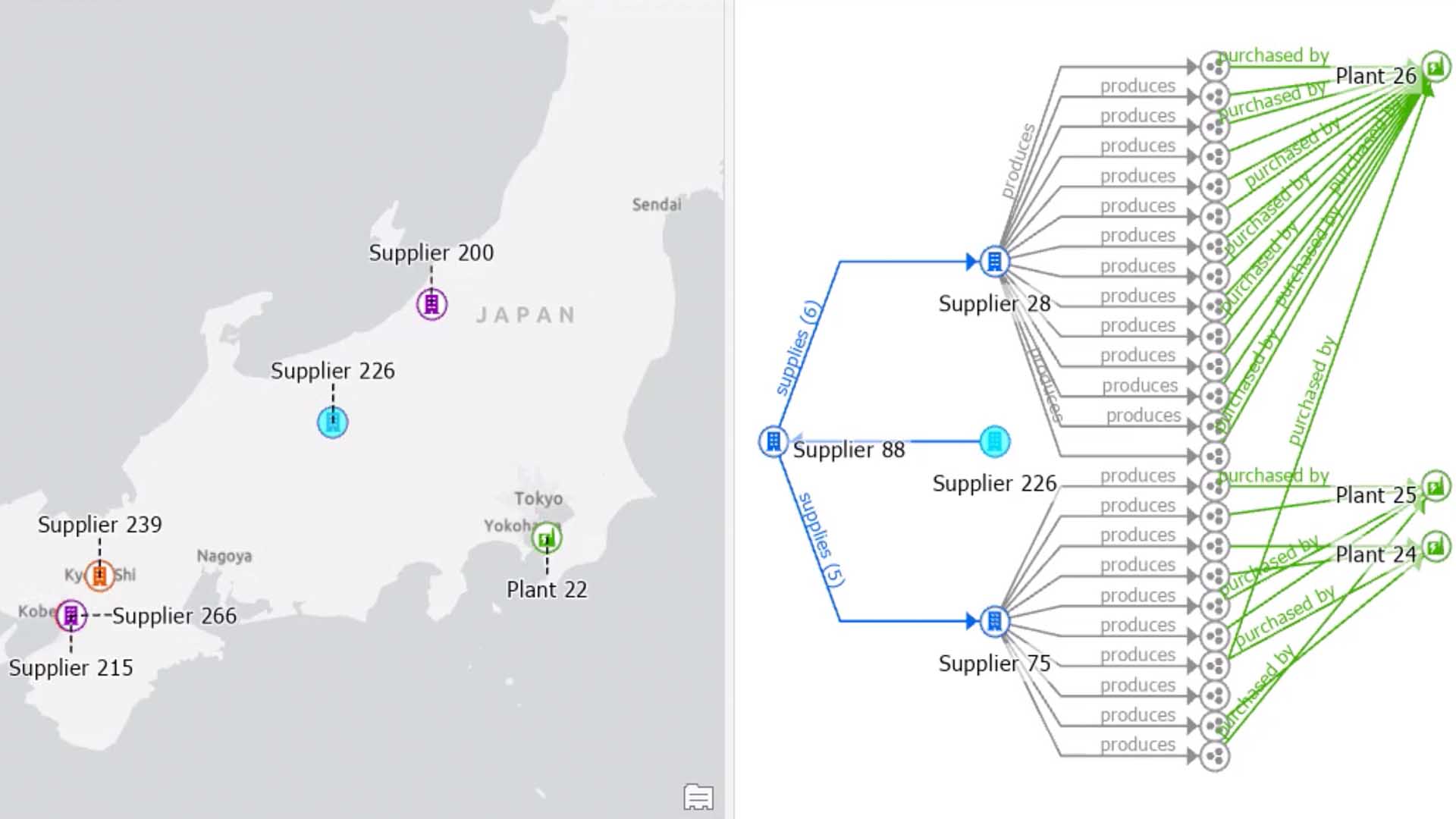

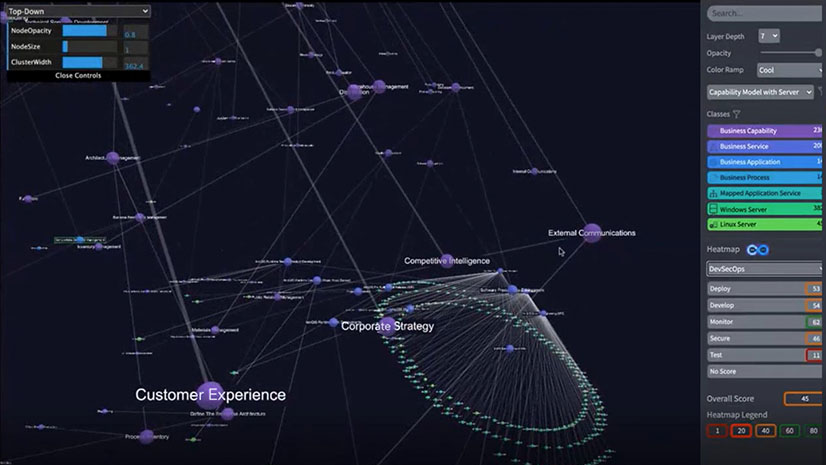

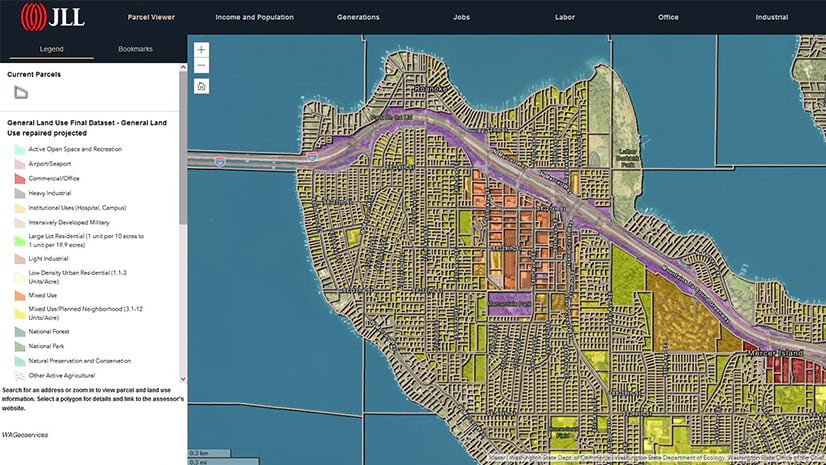

Just as executives monitor the state of a business on smart maps and dashboards, operations managers can monitor manufacturing and warehouse facilities. Digital facility maps created with geographic information systems (GIS) technology reveal the location and condition of assets, allowing viewers to access details like hours in use and repair histories.

Such maps connect to service management systems, allowing operations personnel to initiate work tickets and cut maintenance response times. Manufacturers and logistics providers can pair GIS with reporting dashboards to see which equipment requires the most maintenance or which warehouse aisle is busiest. They can also sync with sensors, cameras, and other IoT devices to create a real-time digital twin of a facility.

Connecting Data Streams for Richer Insights

While operational visibility is a key concern for manufacturing and logistics managers, the capabilities of indoor GIS extend beyond visualization. The software analyzes information about what’s happening where and points to areas of improvement.

For example, a manufacturing or distribution facility might have a series of AI-enabled cameras inspecting products during assembly or sortation, a carrier robot moving products to a pallet, and a sensor measuring the weight of each pallet. Indoor GIS can track each instance a camera flags a defective product, how many trips the carrier robot makes in an hour, or how many times a pallet measures full per day, then extract insights based on distance or patterns of movement.

Each data stream informs immediate actions like quality assurance protocols or warehouse capacity checks. But viewed together on a GIS map, the data tell a bigger story about productivity and process, helping decision-makers understand and predict how one adjustment, like moving a conveyor belt closer to a loading bay, could impact overall operational efficiency.

Bringing Location Intelligence Indoors

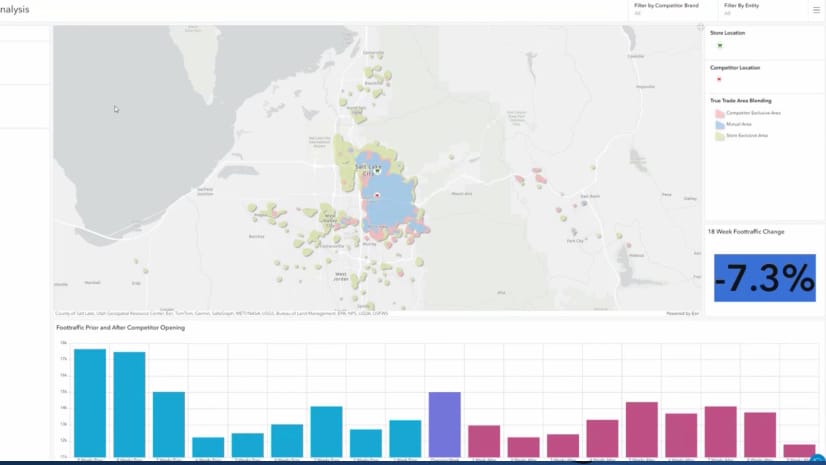

Early adopters of smart mapping technology, including many logistics companies, have long used location intelligence to inform decisions outside core facilities—routing products quickly to customers, for example, or opening a new warehouse in an area with a growing population.

Now, as indoor spaces become smarter, leaders across industries are discovering that location intelligence is equally valuable indoors, where maps reveal patterns that spreadsheets often hide. Only a map can show, for instance, that a common assembly component is stored in a bay far from the line where it’s most used, or that a disproportionate percentage of safety incidents occur near a particular loading dock.

From procurement to fulfillment, these surprising insights can sharpen the competitive edge of automation and the efficiency of indoor operations. With a map to show how disparate technologies connect to form a complete smart system, executives will be better positioned to implement automation technology and optimize its use in ways that make sense for indoor environments.

Photo by Jacques Dillies

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

November 18, 2025 |

November 12, 2018 |

January 6, 2026 |

July 25, 2023 |

December 22, 2025 |