Brown boxes are the workhorse of the modern shipping economy and they’re made from one of the planet’s most valuable resources: trees.

Smaller sized trees are sliced into chips and cooked in digesters to form pulp, which is pressed, dried, and folded—protecting the goods packed into millions of parcels shipped daily.

In the words of Sophie Beckham, chief sustainability officer at International Paper (IP), cardboard boxes are a low-emotion product made from a high-emotion resource. For IP, one of the world’s largest packaging and pulp companies, taking a sustainable approach to forests as a renewable resource is a bedrock principle.

Biodiversity loss threatens the ecosystems that many industries rely on. In response, natural resource companies are embracing technologies that create supply chain visibility, a precondition for monitoring and mitigating environmental damage.

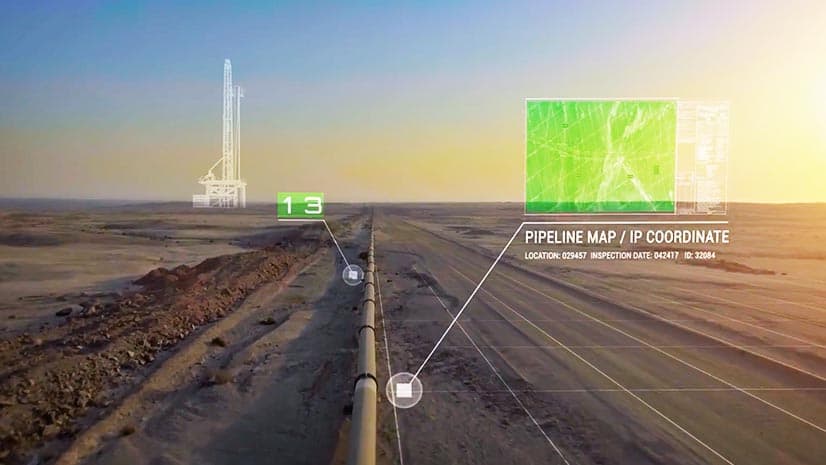

IP created an application named ForSite® that uses geographic information system (GIS) technology and satellite imagery to help the company meet one of its Vision 2030 goals: sourcing 100 percent of its fiber—for packaging materials, tissues, and other products—from sustainably managed forests.

Supply Chain Visibility—Seeing the Forest for the Trees

To educate customers about IP’s environmental practices, ForSite provides detailed supply chain visibility on timber tracts and suppliers. That transparency serves stakeholders both inside and outside the organization.

For the company’s foresters, who purchase wooded tracts from loggers and landowners, ForSite supports a rigorous due diligence process. The GIS software at its core synthesizes satellite imagery and scientific data, giving foresters a clear picture of areas hosting threatened wildlife and waterways or important flora. With this knowledge, members of IP’s fiber supply organization can determine whether environmental risks are too high to proceed or develop plans to protect biodiversity.

Beckham and her team have been impressed by the initial results.

She explains: “Our early experiences with mapping conservation attributes in a few of our fiber sourcing regions provided further evidence that this kind of technology could strengthen our approach to responsible sourcing, deepen our relationship with suppliers through discussions of land management practices, and highlight our lived commitment to our forestry goals.”

For IP’s customers, ForSite’s maps provide a platform for communication and verification that logging is done sustainably. ForSite’s location intelligence has also transformed the procurement process, allowing fiber supply teams to assess price, volume, and delivery distances for each tract. Data from ForSite maps feeds dashboards that IP decision-makers consult throughout the purchasing process.

“Simply put, it helps us make better and faster decisions, and it helps us more quickly and more effectively grow our credibility with customers and other key stakeholders,” says Lee Alexander, IP’s vice president of global fiber supply.

Everything we do is so spatial . . . we needed mapping technology to help us move forward.

How Maps Achieve Supply Chain Transparency

In a recent British study, 67 percent of CEOs said they worry about ESG supply chain transgressions. With some companies sourcing raw materials from thousands of suppliers, supply chain visibility is a top priority across the business world—and essential to sustainable operations.

IP primarily works with private forest landowners in the American Southeast. It sources its fiber from sustainably managed forests, some of which are certified by the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI) programs. However, the company wanted to assure customers that even if forests were not certified—which can be a burdensome process for many small private forest landowners—suppliers are following sustainable forestry practices.

That led Jeremy Poirier, IP’s senior manager of fiber certification and sustainability, and Brian Long, operations planning manager for global fiber supply, to pitch upper management on the concept for ForSite: a platform powered by GIS that could demonstrate IP’s due diligence process to its customers.

“It enables us to have a tract-by-tract conversation prior to purchase to verify that . . . sustainable forest management is occurring,” says Long, who helps manage the technology that supports fiber supply teams.

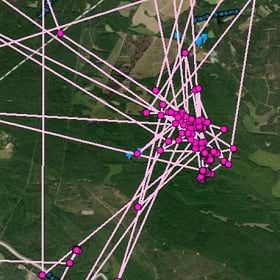

ForSite’s GIS maps show all the active and past timber tracts IP has purchased. A layer on biodiversity data identifies high-value areas where endangered wildlife or priority forest types might be located. If multiple criteria appear in a single area—for instance, contiguous forests with habitat typical of keystone species like longleaf pines or the red-cockaded woodpecker—the map turns red, alerting foresters that the plot needs special attention.

In South Carolina, ForSite’s location intelligence guided IP’s collaboration with a landowner to create 350-foot-wide wildlife corridors where white-tailed deer and wild turkeys roam. Location technology has also helped IP protect the habitats of the gopher tortoise, a threatened species important to the Southeast landscape. On one timber tract, IP foresters flagged the locations of tortoise burrows prior to harvest to ensure they were protected during pine thinning—a beneficial harvest practice for the animal, which feeds on forest undergrowth.

Such supply chain visibility helps IP protect biodiversity and promote the sustainable forestry practices its customers expect.

Building a Smarter Supply Chain

When Poirier shares ForSite’s maps with customers, they are often impressed at the amount of technological savvy that goes into sustainable sourcing. “When they see it in real time, I think it really drives home the commitment,” he says. “It just makes the whole supply chain come to life.”

In the past, IP might only have known where wood was coming from on a county level. ForSite’s GIS technology enabled them to trace and review fiber tract by tract.

This system of record enables the procurement team to make smarter pricing decisions and ensure cost-effective deliveries. IP managers can consult maps or dashboards to evaluate factors like forest age, ground conditions, and the status of harvesting and thinning, and find contact information for procurement reps. They can determine whether timber prices are fair based on regional comparisons and distance and fuel rates.

ForSite’s supply chain visibility also saves employees trips to the field. Through remote sensing, fiber supply team members see that harvesting has begun, and can plan a timely site visit. Managers verify that wood is in fact coming from the location agreed upon with a supplier.

“It has made our procurement system more consistent across our entire footprint,” Alexander says. “It’s allowing us to build an incredibly robust digital procurement library we use for real-time queries to aid in daily decisions.”

It makes me feel good that we’ve come a long way to be able to help support the forest products industry, record what we’re doing, and show it to folks.

When the Supply Chains of Business and Nature Intertwine

One of ForSite’s biggest conservation wins came when during a post-harvest tract inspection, when an IP forester in South Carolina discovered the nest of a swallow-tailed kite within a streamside management zone adjacent to the recent harvest area.

The location was logged in ForSite and the forest landowner agreed to allow IP and one of its conservation partners, the American Bird Conservancy (ABC), to catch one of the adult kites and fit it with a transmitter. This allowed IP and ABC biologists to map the kite’s movements in the area and then track its migration from South Carolina to Brazil—an epic journey of thousands of miles.

It was a rousing reminder that the supply networks of modern industry are deeply intertwined with the natural supply chains that sustain wild animals, plants, and waterways. GIS technology gives companies like IP a real-time view of operations to ensure that the two worlds can coexist.

“[ForSite] is an excellent way to connect customers with the value of a working forest,” Poirier says. “It’s a powerful visual spatial demonstration of how we can responsibly and sustainably source wood fiber to make fiber-based products people depend on every day.”

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

July 25, 2023 |

November 12, 2018 |

April 1, 2025 |

April 29, 2025 |

February 1, 2022 |