With nearly 9,000 kilometers (about 5,500 miles) of railroad track packed into 30,000 square kilometers (about 19,000 square miles) of land, Belgium’s national railway is one of Europe’s busiest. For government agency Infrabel, which manages all of Belgium’s railway infrastructure—including train tracks, power stations, and underground cables—safety is a major concern.

“Infrabel provides the backbone for everyone in Belgium to travel by train throughout the country,” said Damien Paque, team leader of geoservices and solutions at Infrabel. “The first and biggest priority for us is to be able to provide more safety to our workers in the field.”

Crew members in rail yards sometimes work within five meters of active tracks, so precision and accuracy are vital for Infrabel. That’s why Paque and his team have spent the last few years developing an innovative deployment of geospatial technology. The system consists of a robust GIS and several apps that combine advanced technologies such as Global Navigation Satellite System (GNSS) devices, local positioning, and geofencing. One app in particular tracks mobile crew members in real time down to the decimeter, or subfoot, level—a groundbreaking way to improve safety.

“What they’ve done is brilliant,” said Terry Bills, Esri’s transportation industry manager. “Infrabel is developing a solution to the number-one challenge railroad companies worldwide face, which is protecting workers.”

A Single Source of Up-to-Date Infrastructure Data

The first step in creating a safer work environment is having accurate data on infrastructure. That’s where Infrabel’s GIS journey began.

Previously, the agency’s infrastructure data was recorded in a variety of formats. In 2018, Infrabel adopted ArcGIS technology to consolidate and improve infrastructure records. Paque and his team built tools to digitize as-built records, georeference computer-aided design (CAD) drawings, and survey the entire rail network to validate asset locations. Those tools also allowed them to georeference photos taken by cameras placed on trains and incorporate high-precision aerial drone imagery of Belgium’s rail system.

The result of all this is InfraGIS, a single source of accurate and up-to-date geospatial data for all the rail infrastructure that Infrabel oversees.

“The goal is to have good management of this data, so we have built a repository where we can have this information,” Paque explained.

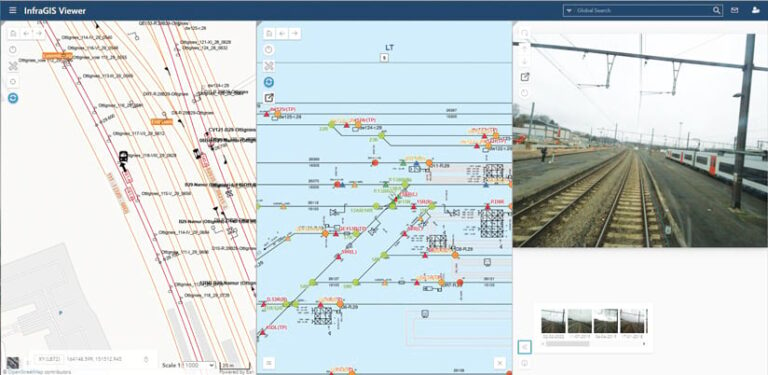

The data in InfraGIS is made available to approximately 10,000 Infrabel employees through an app called InfraGIS Viewer. Built within ArcGIS Enterprise and using ArcGIS API for JavaScript, InfraGIS Viewer consists of three synchronized viewers. Geographic Viewer offers a map view of railway infrastructure and is used for asset and workforce management. Schematic Viewer provides a dynamic, schematic representation of the rail network and assets and is often used in planning and train traffic management. RailView shows a photographic view of infrastructure, which office-based employees can use to get a glimpse of what’s happening in the field.

Data is synchronized among the three viewers. For example, when a user pans or zooms in Geographic Viewer, the view is reflected immediately within both Schematic Viewer and RailView.

InfraGIS Viewer is now the most-used cartographic app at Infrabel. It plays a primary role in managing worker safety, and its success enabled the agency’s technology team to develop two ambitious geospatial mobile apps: !nfraSPAD and Virtual Fencing.

Alerting Train Conductors of Danger Ahead

When maintenance crews work in the rail yard, numerous logistics must be coordinated to provide them with a safe work site. This often includes taking segments of track out of service to ensure that trains don’t operate where crews are.

“You don’t want the two—trains and work crews—to mix,” said Bills.

A red signal is what tells train conductors where not to go. If a train does cross a red signal, it is known as a signal passed at danger, or SPAD.

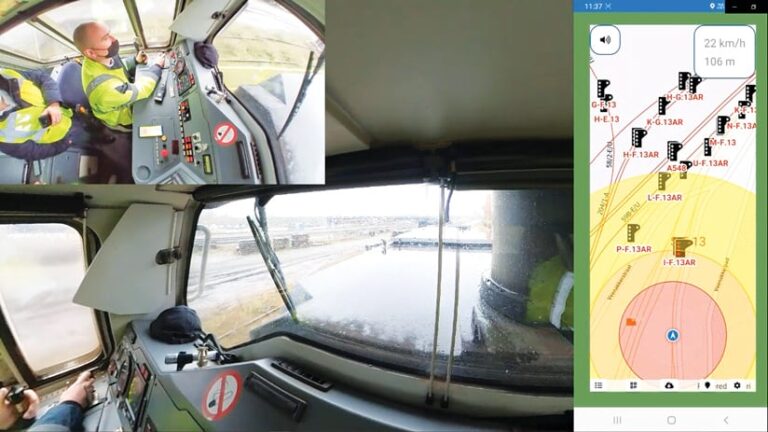

To reduce potential hazards from SPADs, Infrabel created !nfraSPAD, a critical alert app developed with ArcGIS API for JavaScript that informs train conductors (and subcontractors) and their supervisors when they are approaching a red signal.

When !nfraSPAD detects a red signal ahead, it immediately sets up three default geofences, or buffer zones, 150 meters from the signal, 80 meters from the signal, and 50 meters from the signal. When the train passes through each buffer, the app sends progressively louder and more jarring warnings to a location tracking device, such as a smartphone or tablet, that every train conductor and supervisor at Infrabel carries. For example, a yellow, moderately loud and vibrating alarm that goes off at 150 meters from the signal will turn into a red, much louder, more intensely vibrating alarm at 50 meters. This maximizes the likelihood that the train conductor will know to proceed with caution and be prepared to slow down or stop.

The conductors’ tracking devices are accurate to about 10 meters, which is standard for most smartphones and tablets.

Tracking Mobile Crews Precisely, in Real Time

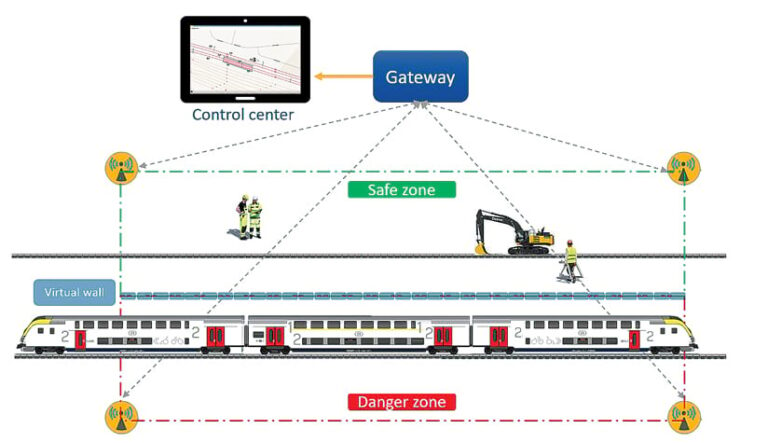

For mobile crews and their supervisors, the Virtual Fencing app, which is under development, will be even more precise. It will alert mobile crews and their supervisors if a worker enters a high-danger area in the rail yard, like a section with live track. Because the virtual fences that the app relies on are based on GNSS and ultra-wideband (UWB) positioning technology, these alerts will be accurate to within 10 centimeters.

To yield this level of reliability, Infrabel is effectively creating its own high-accuracy, location-tracking mesh network. For places along the rail network where there is no GNSS connectivity, such as in tunnels, Paque and his team are installing UWB positioning beacons every 100–200 meters. The team is surveying the beacons using Arrow Gold GNSS receivers from Esri partner Eos Positioning Systems. These receivers use differential corrections from local real-time kinematic (RTK) networks to record centimeter-accurate coordinates in the geodatabase.

“With this level of accuracy from the Arrow Gold, we can get a precision of a few centimeters for the location of each beacon,” said Infrabel technical GIS manager Jérôme Duckers.

The net effect of the beacons being so precisely located is that, together, they can track human movement throughout the area to within 10 centimeters of where the person actually is.

All Infrabel mobile workers will carry lightweight positioning tags in the pockets of their smart, high-visibility vests when they work in the field. The tags, which are approved for use in live-rail environments, will track each worker’s movement throughout the beacon network.

In addition, Infrabel’s technology team will use geofencing in ArcGIS Pro to create a virtual wall around the crew’s work space and divide the area into safe zones and danger zones.

“There is a safe zone, in which the maintenance workers can keep working on their track, and a danger zone that they should not enter,” Paque said.

The moment any workers cross into a danger zone, they and their supervisors will receive alerts. The supervisor’s tablet will flash and make noise, and the crew member’s high-visibility vest will vibrate, flash, and sound an alarm.

“When this happens, the supervisor and worker will both know that the worker needs to move back to the safe zone immediately,” said Paque.

This high-precision, scalable location-tracking technology could have widespread implications for the railroad industry. Knowing—in real time—the exact location of all mobile workers in the rail yard and being able to send them alerts when they need to get out of danger enable rail operators to keep their workers safe in a whole new way.

Routing Workers and Emergency Crews More Safely

Minimizing the time spent in a live rail environment is another way railway companies can improve safety. To do that, Infrabel developed an additional mobile app called Access to Railway. The agency makes it available to staff members and emergency services so that they all have more efficient access to assets.

Built using ArcGIS Runtime SDK for .NET, Access to Railway contains a list of all the rail network’s points of access, such as stations and crossings. When maintenance workers are called in to repair a switch or emergency personnel need to respond to an accident, they can launch Access to Railway on a tablet and see the safest and most efficient way to get there. Directions in the app include how to get from where they are to the Infrabel facility containing the equipment they need, from the facility to the parking location closest to the asset, and from the parking location to the nearest rail yard access point (which is typically outside the public road network).

While many third-party apps could optimize either a driving route or a route within an asset network, Access to Railway does both. This ensures that mobile crews; emergency service personnel; and soon, Infrabel subcontractors spend the least amount of time navigating to, from, and within the yard.

Visualizing Nonvisible Assets with Augmented Reality

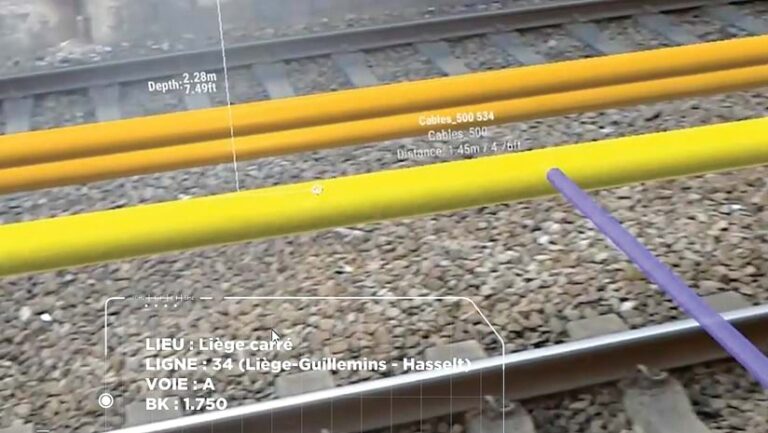

Looking ahead, Paque and his team want to help crews stay safe when working near nonvisible underground cables by using augmented reality (AR) to visualize the cables’ locations.

“When you can see the cables underground, you can avoid accidents when working in the field,” Paque said. “With this AR help, the goal is to show those cables to the workers, superimposed on their actual view of the work site.”

Before deploying the AR visualization, however, Paque and Duckers need to enhance the data Infrabel has on its underground cable network.

“The location data from the previously digitized CAD drawings has proven, overall, to be not accurate enough for an AR application,” said Paque. “We are looking into ways to improve the quality of this data so that, ultimately, we can use AR technology on our construction sites.”

Once the data is ready, Paque and his team would like to implement an AR app that projects buried infrastructure assets via a HoloLens device. When connected to an Arrow Gold GNSS receiver, the app can precisely orient crew members to their position relative to buried assets.

According to Bills, Infrabel is taking a lead in the rail industry when it comes to addressing safety challenges.

“The ability to know and understand the location of all your assets with extremely high accuracy is critical to safety in the rail industry worldwide,” he said. “What Infrabel has done is highly innovative. Along with some of the work that other railway organizations in the region are doing, it charts a path for others to follow.”